PRODUCT CATALOGS

PROFESSIONAL INTELLIGENT PACKAGING EQUIPMENT SYSTEM SOLUTION PROVIDER

Huaxiao: Professional Packaging Machine Manufacturer in China

From single machines to complete lines, Huaxiao delivers end-of-line packaging solutions that ensure a seamless finish to your production process. We offer a diversified portfolio of over 200 models across seven product categories—all serialized for mass production. These include sealers, vacuum packers, baggers, carton sealers, strappers, shrink wrappers, and thermoforming machines. Choose Huaxiao as your trusted partner for automated, high-quality, and reliable packaging.

Frequently Asked Questions

Huaxiao: Leading Chinese manufacturer of advanced packaging solutions for the food and medical industries

A: These are common issues with clear solutions : ① Insufficient vacuum: Check if the vacuum pump oil is contaminated (replace if needed) or if seals are worn (replace with spare parts we provide); ② Poor heat sealing: Adjust temperature (increase by 5-10℃ for thick films) or clean the heating strip (remove oxide with a dry cloth) . Our 24/7 technical team offers WhatsApp/Skype video guidance for complex issues.

A: Our machines adopt energy-saving designs—double-chamber vacuum models save 30% energy vs. single-chamber ones, and automatic VFFS machines consume only 8-12 kWh/day . Durability is guaranteed by imported components (e.g., German Becker vacuum pumps): continuous 8-hour operation is supported, with an average lifespan of 8-10 years (industry average: 5-6 years) . We provide 1-year full warranty + 2-year core parts warranty.

A: Lead time: 15-25 days for standard models (e.g., basic vacuum sealers), 25-35 days for customized versions (e.g., multi-language touch screen, special certification) . Payment terms are flexible for global buyers: T/T (30% deposit + 70% before shipment), L/C (for large orders), and we support FOB/CIF/EXW trade terms .

Unlimited Resouce

Provides a comprehensive range of end-of-line packaging machinery

Why Choose Us Packaging Machine Suppliers and Manufacturers?

Factory

Self-owned factories, quality, and delivery are more controllable.

Experience

20+ years of manufacturing experience since 2004.

Equipment

Imported German equipment, product performance is stable.

Service

7X24 hours online communication.

Our vacuum packaging machines and blister machines are optimized for different global working conditions , with universal voltage design and dust-proof, corrosion-resistant structure, adapting to various industrial environments easily.

Whether you need small-scale desktop packaging machines or large industrial automatic lines, we provide one-stop customized solutions. Professional export team takes care of all procedures: logistics arrangement, customs declaration, document preparation, and freight tracking.

24/7 online after-sales service via call, email and video; free replacement of vulnerable parts within 1 year. Cooperative after-sales agents in core global markets realize fast on-site maintenance, ensuring your production is not interrupted.

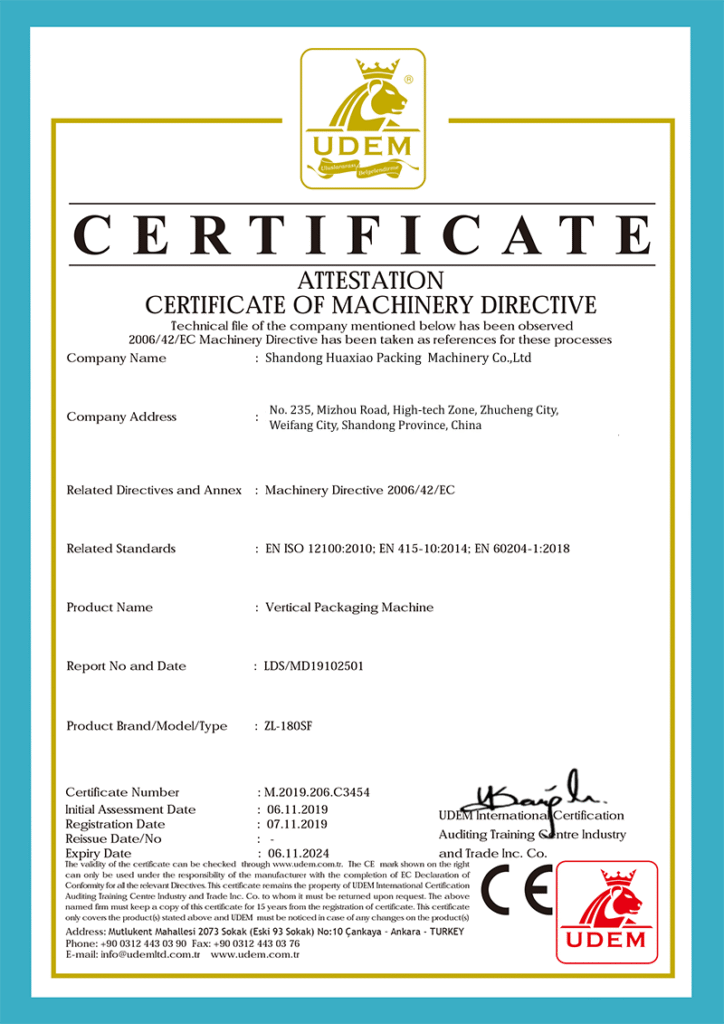

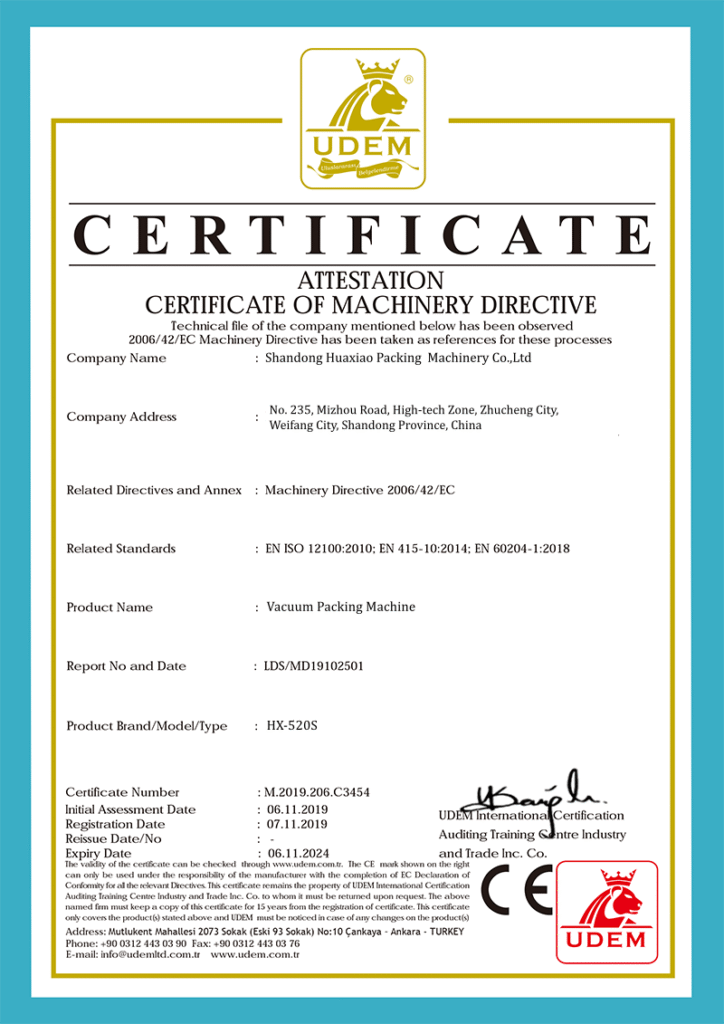

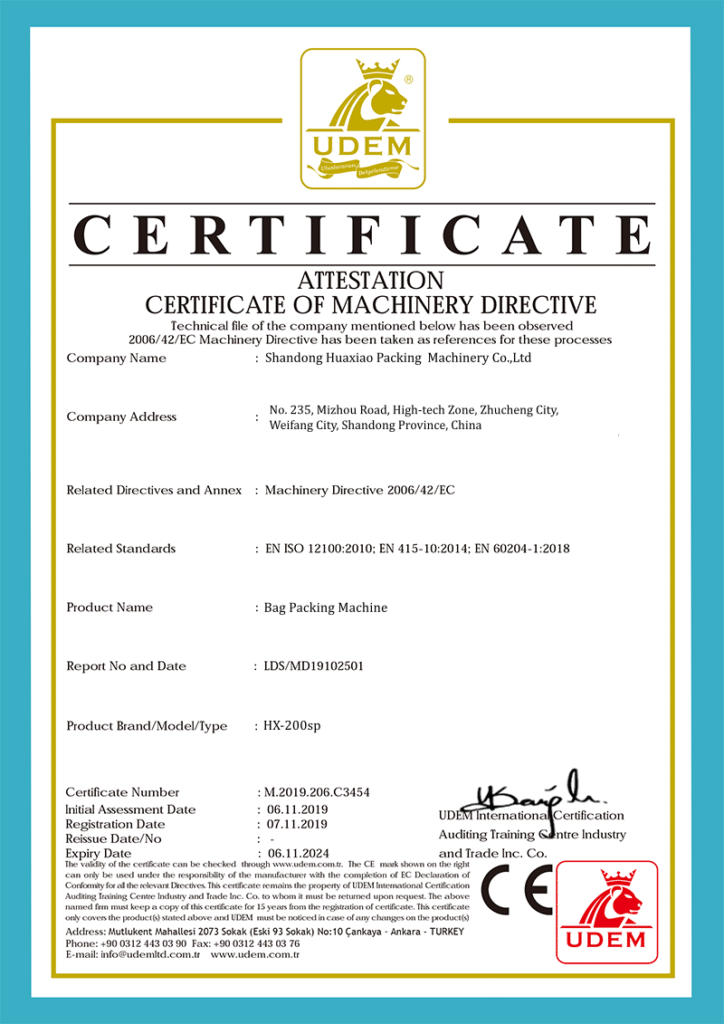

Our Certificate

Strictly comply with international quality norms, CE/ISO/SGS certified products help you smoothly pass local customs inspection and market access. Each packaging machine is equipped with complete certification documents, avoiding import risks and extra costs.

CUSTOMER CASE

Stepping Press Equipment Annual Production Calculator

Precision Calculation for Press Equipment Annual Capacity | Multi-Model Comparison Analysis

Input Parameters

Calculation Formula

Production Results

Calculation Summary

Model Comparison

Packaging Industry News and Event