Vacuum Forming: A Comprehensive Guide to Thermoforming Plastic Sheets

What is Vacuum Forming?

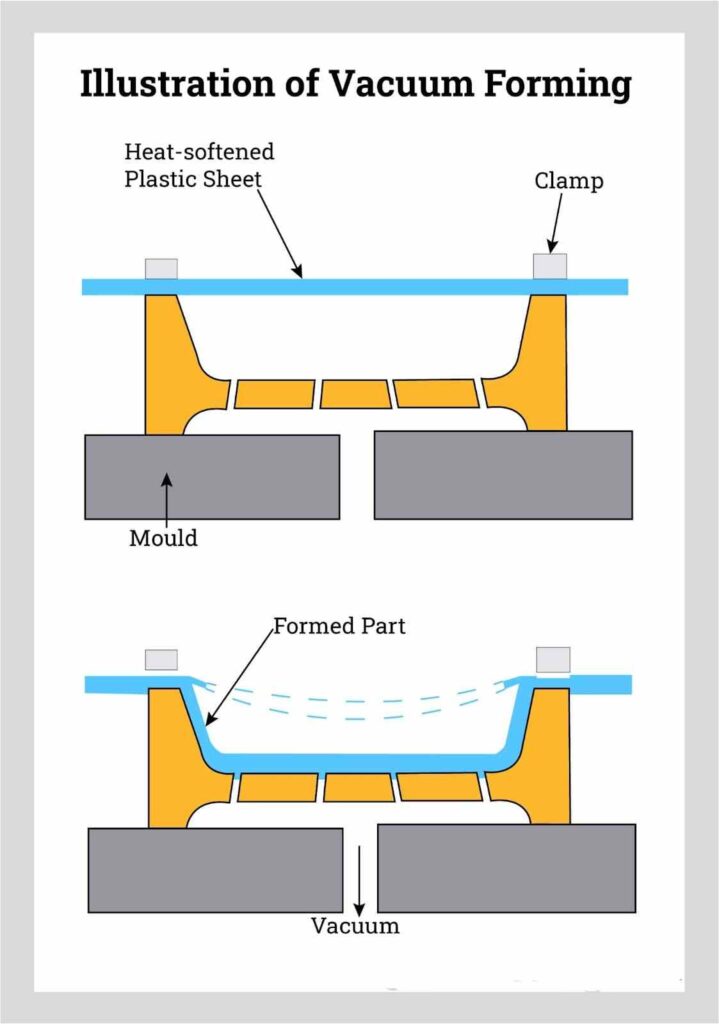

How Does the Vacuum Forming Process Work?

1. Mold Preparation

- Prototyping/Small Batches: Molds made from wood, foam, or 3D-printed plastic (cost-effective, quick to produce).

- Medium-to-High Volume: Molds made from aluminum or steel (durable, heat-resistant, and suitable for repeated use).

2. Material Selection & Cutting

- PVC: Affordable, versatile, and ideal for signage, packaging, and consumer goods.

- Acrylic (PMMA): Transparent, scratch-resistant, and used for displays, lighting fixtures, and decorative panels.

- ABS: Durable, impact-resistant, and suitable for industrial parts, cosplay props, and automotive components.

- PETG: Food-safe, recyclable, and used for packaging, medical devices, and retail displays.

- PP/PS: Lightweight, cost-effective, and common in disposable packaging and consumer products.

3. Heating the Plastic Sheet

- Uniformity: Even heating ensures the sheet softens consistently, preventing uneven stretching or thinning.

- Temperature Control: Overheating can cause the sheet to degrade or bubble; underheating results in incomplete forming.

- Heating Time: Varies by material thickness (thin sheets: 30–60 seconds; thick sheets: 2–5 minutes).

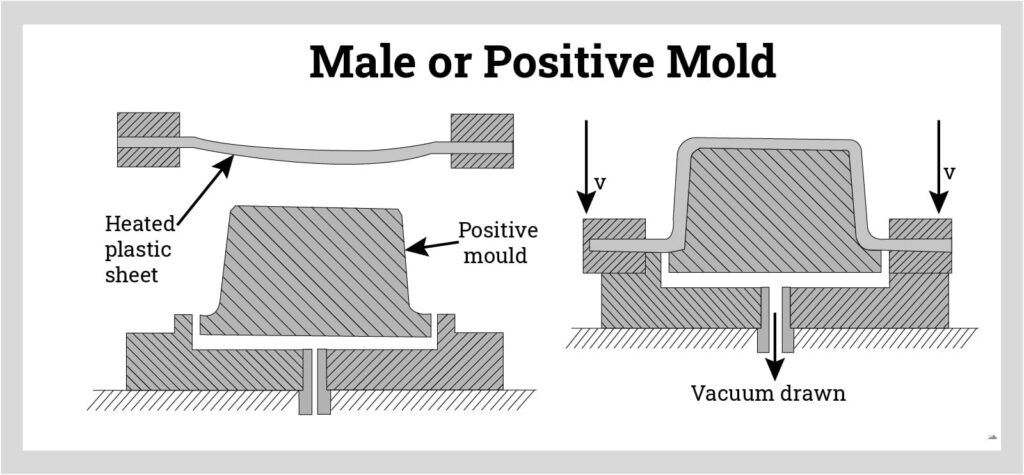

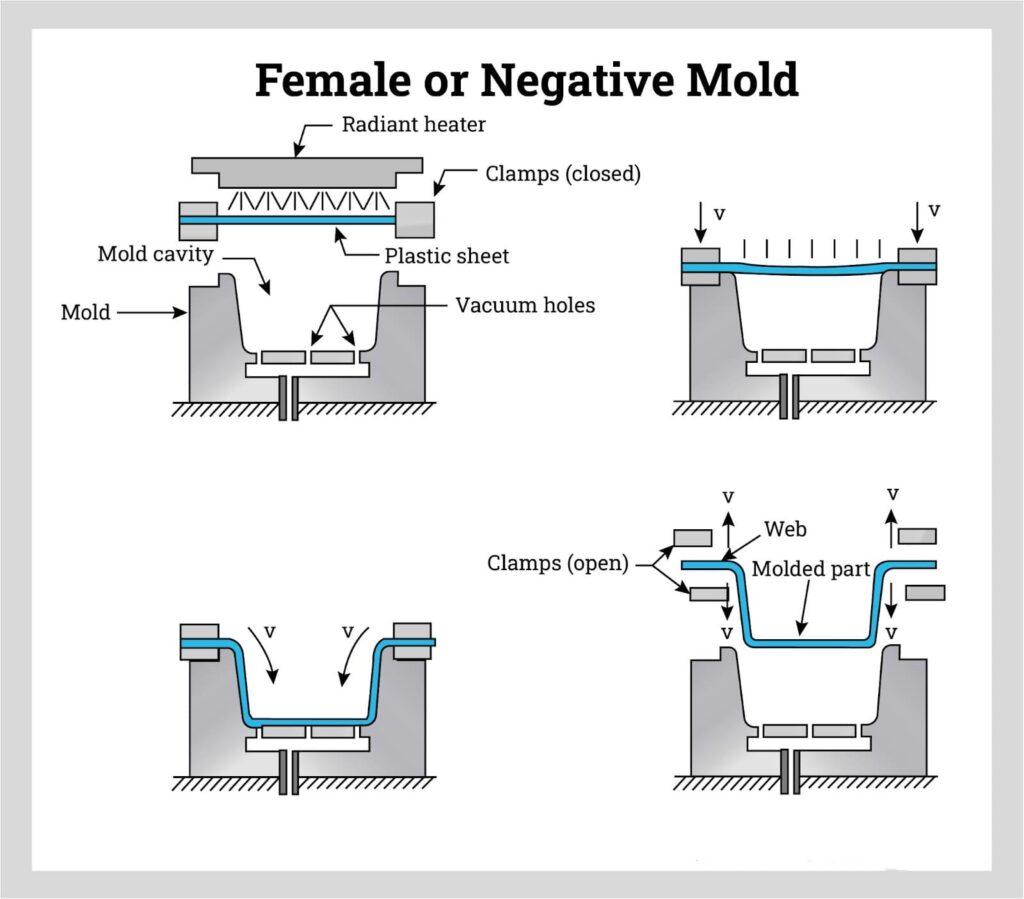

4. Forming the Plastic

- Plug Assist: A solid plug pushes the sheet into the mold before vacuum is applied, ensuring even stretching.

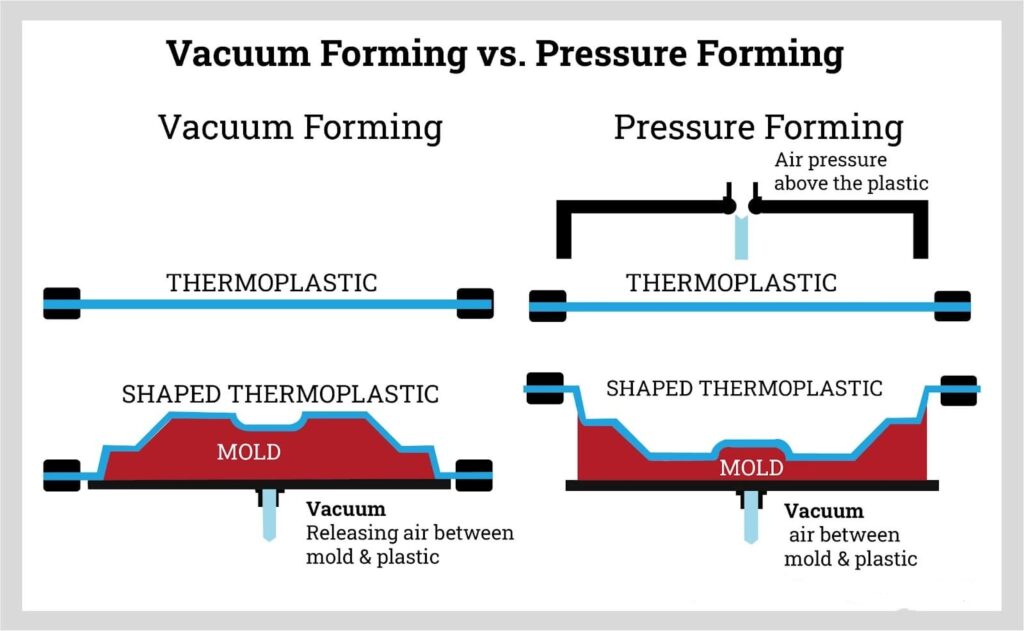

- Pressure Forming: Combining vacuum pressure with positive air pressure (from above the sheet) for tighter mold adherence.

5. Cooling & Solidification

- Air Cooling: Blowing ambient or chilled air over the part (fast, cost-effective for most applications).

- Water Cooling: Molds with built-in water channels for faster cooling (ideal for high-volume production).

6. Trimming & Finishing

- Sanding or polishing to smooth edges.

- Drilling holes for assembly.

- Painting, printing, or laminating for aesthetic or functional purposes.

Types of Vacuum Forming Machines

1. Manual Vacuum Forming Machines

- Best For: Prototyping, small workshops, and low-volume production (e.g., DIY cosplay props, custom home decor).

- Features: Manual clamping, heating, and mold positioning—affordable and easy to operate.

- Limitations: Limited to small-to-medium sized parts; slower production speed.

2. Semi-Automatic Vacuum Forming Machines

- Best For: Medium-volume production, small businesses, and industrial workshops.

- Features: Automated heating and vacuum cycles; manual mold loading/unloading.

- Advantages: Faster than manual machines; consistent results; suitable for large-format parts (e.g., advertising billboards, automotive interior panels).

3. Fully Automatic Vacuum Forming Machines

- Best For: High-volume production, industrial manufacturing, and precision parts (e.g., medical devices, packaging).

- Features: Automated sheet feeding, heating, forming, cooling, trimming, and stacking.

- Advantages: High throughput (hundreds to thousands of parts per hour); minimal operator intervention; tight dimensional control.

4. Large-Format Vacuum Forming Machines

- Best For: Big thermoforming pieces (e.g., large signs, architectural panels, industrial molds).

- Features: Extended worktables (up to 12’x24’ or larger); high-power heating systems; deep forming capabilities.

- Example: The BSX-1224 Vacuum Forming Machine—designed for large-scale 3D thermoforming of Acrylic, ABS, and PVC, with adjustable material sizes and fast uniform heating.

Key Advantages of Vacuum Forming

1. Cost-Effective Tooling & Production

- Mold costs are 50–90% lower than injection molding (especially for large or custom parts).

- Low setup costs make it feasible for prototyping and small-batch runs.

- Material waste is minimal (scrap can often be recycled).

2. Versatility in Design & Materials

- Accommodates complex shapes, deep cavities, and intricate details.

- Works with a wide range of thermoplastics (PVC, Acrylic, ABS, PETG, etc.).

- Suitable for small parts (e.g., electronic enclosures) and large-format products (e.g., 10’+ billboards).

3. Efficiency & Speed

- Quick mold setup (prototyping molds can be ready in days, not weeks).

- Fast production cycles (especially with automatic machines).

- Ideal for time-sensitive projects or short lead times.

4. Durability & Quality

- Produces parts with consistent thickness, strength, and surface finish.

- Thermoplastics offer excellent durability, impact resistance, and chemical resistance (depending on material).

- Suitable for food-safe, medical-grade, and industrial-grade applications.

Common Applications of Vacuum Forming

1. Advertising & Signage

- Acrylic lettering and logos.

- Large-format billboards and illuminated signs.

- Retail displays and point-of-purchase (POP) stands.

2. Packaging

- Blister packs for electronics, toys, and medical devices.

- Food trays (e.g., deli containers, fast-food packaging).

- Protective packaging for industrial parts.

3. Automotive & Transportation

- Interior panels (door panels, dashboard trim).

- Exterior components (bumpers, fender flares).

- Cargo liners and storage solutions.

4. Cosplay & Entertainment

- Custom props (armor, weapons, masks).

- Costume accessories and set pieces for film/TV.

5. Home Decor & Furniture

- Decorative panels and wall art.

- Custom storage solutions (shelves, bins).

- Furniture components (chair backs, table tops).

6. Medical & Healthcare

- Disposable medical devices (trays, housings).

- Medical equipment enclosures (MRI/CT scan components).

- Food-safe and sterile packaging.

7. Industrial & Manufacturing

- Industrial molds and templates.

- Machine guards and covers.

- Architectural panels and building materials.

How to Choose the Right Vacuum Forming Machine

1. Production Volume

- Small batches/prototyping: Manual or semi-automatic machine.

- Medium-to-high volume: Semi-automatic or fully automatic machine.

2. Part Size & Dimensions

- Small parts (≤24”x24”): Compact manual machine.

- Large parts (≥48”x48”): Large-format semi-automatic or automatic machine (e.g., BSX-1224).

3. Material Type & Thickness

- Thin sheets (≤0.125”): Standard heating system.

- Thick sheets (≥0.25”): High-power heating system with extended heating time.

- Specialized materials (e.g., medical-grade PETG): Machine with precise temperature control.

4. Precision Requirements

- High precision (e.g., medical devices): Automatic machine with digital controls.

- General use (e.g., signage): Semi-automatic machine with basic controls.

5. Budget & ROI

- Startups/small businesses: Affordable manual or semi-automatic machine.

- Industrial manufacturers: Invest in fully automatic machines for long-term efficiency.

Vacuum Forming vs. Other Thermoforming Processes

|

Process

|

Key Difference

|

Best For

|

|

Vacuum Forming

|

Uses only vacuum pressure to shape plastic

|

Large parts, low-to-medium volume, custom designs

|

|

Pressure Forming

|

Combines vacuum + positive air pressure

|

High-precision parts, tight tolerances

|

|

Injection Molding

|

Injects molten plastic into a mold

|

High-volume production, small-to-medium parts

|

|

Blow Molding

|

Uses air pressure to inflate plastic into a mold

|

Hollow parts (bottles, containers)

|

FAQs About Vacuum Forming

Q: What is the maximum size of a part I can vacuum form?

Q: How long does it take to produce a vacuum formed part?

Q: Can vacuum forming be used for food-safe or medical applications?

Q: Is vacuum forming suitable for prototyping?

Q: What is the typical cost of a vacuum forming machine?

Final Thoughts