Global Buyer’s Guide: How to Choose the Best Automatic Thermoforming Vacuum Packaging Machine Brand

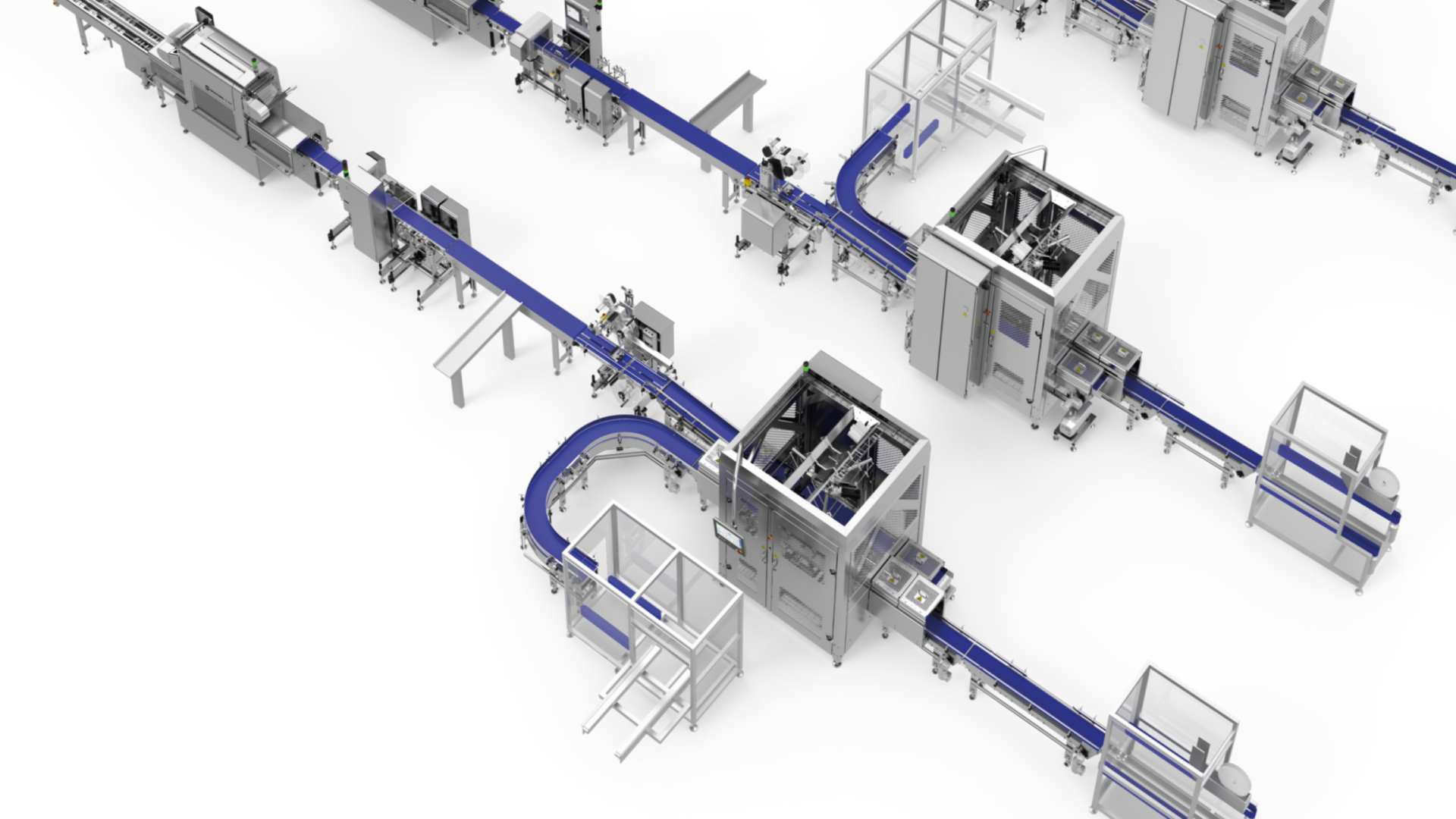

In the global packaging industry, automatic thermoforming vacuum packaging machines have become indispensable equipment for businesses ranging from food processing to medical supplies. These machines offer unparalleled efficiency, consistency, and product protection by forming custom packaging shapes and removing air to extend shelf life. However, with countless brands competing in the global market—from well-established European manufacturers to innovative Asian suppliers—choosing the right one can be a daunting task for international buyers.

As a global buyer, your search for the perfect automatic thermoforming vacuum packaging machine brand likely focuses on reliability, technical performance, cost-effectiveness, and after-sales support. This guide is tailored to your search habits, breaking down the key factors to consider and highlighting top brands across regions to help you make an informed decision.

Key Factors Global Buyers Should Prioritize When Selecting a Brand

Before diving into specific brands, it’s critical to define your core requirements. Global markets have diverse regulations, application needs, and supply chain considerations—here’s what to prioritize:

1. Industry-Specific Expertise and Compliance

Different industries (e.g., food, medical, aerospace) have strict packaging standards. For example, medical packaging requires compliance with ISO 13485, while food processing demands FDA-approved materials and hygiene certifications. Top brands specialize in serving specific sectors: medical buyers should look for brands with a proven track record in sterile packaging, such as Colimatica USA or MULTIVAC, while food manufacturers may prioritize brands optimized for high-volume, moisture-resistant packaging.

Always verify if the brand’s machines meet regional regulations—whether it’s EU CE marking, US FDA standards, or Asian market certifications. Non-compliant equipment can lead to costly delays or rejections in your supply chain.

2. Technical Performance and Customization Capabilities

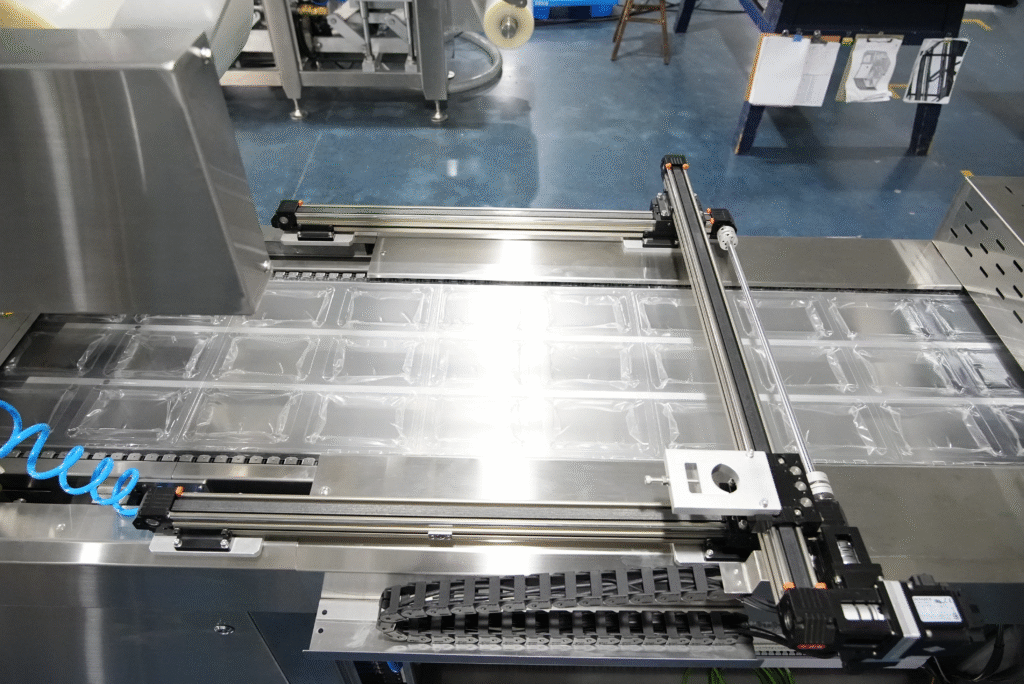

Automatic thermoforming vacuum packaging machines vary in speed, material compatibility, and customization options. Global buyers often search for machines that can adapt to local packaging materials (e.g., biodegradable films in Europe, cost-effective plastics in Asia) and production scales. Key technical metrics to compare include:

- Production speed (units per minute): Critical for high-volume operations in food and consumer goods.

- Material versatility: Ability to work with different film types (PVC, PP, biodegradable materials) to align with regional sustainability trends.

- Customization: Does the brand offer tailored solutions for unique product shapes (e.g., medical devices, irregular food items) or integration with existing production lines

Brands like Formech Inc and PWK Engineering Thermoformer are renowned for their technical precision, while Asian brands such as Allpack and Yongchang Intelligent (YOUNGSUN) excel in customizable, cost-effective solutions for diverse applications.

3. Global After-Sales Support and Supply Chain Resilience

For international buyers, after-sales support is non-negotiable. A brand with a global service network—including local technicians, spare parts warehouses, and multilingual support—can minimize downtime. For example, brands like MULTIVAC and AMAC Technologies have service centers across North America, Europe, and Asia, ensuring quick responses to maintenance needs.

Additionally, consider supply chain resilience. Post-pandemic, global buyers prioritize brands with stable component sourcing and flexible delivery options. Regional manufacturers (e.g., Ridat in India, Supervac in Austria) may offer faster delivery times for local markets, while Chinese brands like Allpack benefit from a robust manufacturing ecosystem that supports scalable production.

4. Cost-Effectiveness and Total Ownership Cost

While upfront cost is a key search term for global buyers, it’s essential to calculate the total ownership cost (TOC), which includes maintenance, energy consumption, and spare parts expenses. European brands (e.g., Henkelman, Webomatic) often have higher upfront costs but lower long-term maintenance expenses due to durable components. In contrast, Asian brands offer competitive upfront pricing, making them ideal for small to medium-sized businesses (SMBs) with budget constraints.

For example, HUALIAN from China offers machines with global voltage compatibility and annualoutput exceeding 100,000 units, providing cost-effective options for buyers in emerging markets.

Top Regional Brands to Consider for Global Buyers

Global buyers often search for region-specific brands to leverage local expertise and support. Below are leading brands categorized by region, along with their core strengths:

North America

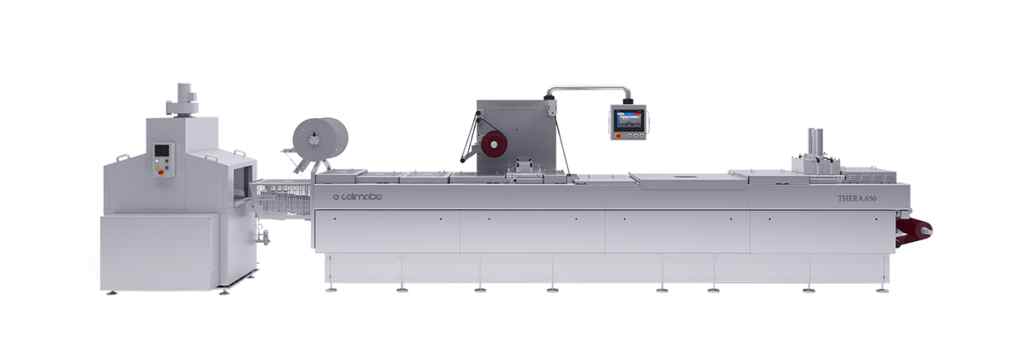

Colimatica USA: A division of Coli Group SPA, specializing in medical and food packaging solutions. Their Thera 650 thermoforming machine offers variable size technology, high efficiency (seals in 20 seconds), and AISI 304 stainless steel construction for hygiene. Ideal for buyers prioritizing compliance and versatility.

AMAC Technologies: With over 40 years of experience, AMAC is a leader in high-volume packaging equipment. Their machines are known for reliability and seamless integration with existing production lines, making them popular among large food and beverage manufacturers.

Europe

MULTIVAC: A German brand and inventor of thermoforming stretch film packaging machines. Renowned for precision, durability, and compliance with strict European medical and food standards. Trusted by global giants in the pharmaceutical and premium food sectors.

Henkelman (Netherlands): Specializes in compact, energy-efficient machines for small to medium operations. Their vacuum packaging solutions are popular among European SMEs due to easy operation and low maintenance costs.

Webomatic (Germany): Focuses on sustainable packaging technology, offering machines compatible with biodegradable films. Ideal for buyers prioritizing environmental compliance (e.g., EU’s plastic reduction directives).

Asia

Hualian (China): Ranked among the top 10 global vacuum packaging machine manufacturers, Hualian offers cost-effective, customizable solutions for diverse industries. Their machines are exported to over 100 countries, with a strong focus on after-sales support for global buyers.

Yongchang Intelligent (YOUNGSUN, China): A leading domestic brand with 500+ patents and exports to 50+ countries. Specializes in integrated packaging lines for large-scale food processors and cold chain logistics applications.

Ridat (India): A key player in the Asian market, offering a wide range of thermoforming machines for food, medical, and consumer goods. Known for competitive pricing and adaptability to local material requirements.

Final Tips for Global Buyers

- Request a demo or sample run: Reputable brands will offer virtual or on-site demos to test machine performance with your specific products and materials.

- Check customer reviews across regions: Use global B2B platforms (e.g., Alibaba, Made-in-China) to read reviews from buyers in your target market—this reveals real-world reliability and support quality.

- Negotiate regional service agreements: Ensure your contract includes local after-sales support, spare parts delivery timelines, and training for your team.

Choosing the right automatic thermoforming vacuum packaging machine brand is a strategic decision that impacts your production efficiency, compliance, and bottom line. By prioritizing industry expertise, technical performance, global support, and cost-effectiveness, you can narrow down your options and select a brand that aligns with your global business goals. Whether you opt for a European leader in precision, an Asian innovator in cost-effectiveness, or a North American specialist in industry-specific solutions, the key is to partner with a brand that understands your unique regional and operational needs.