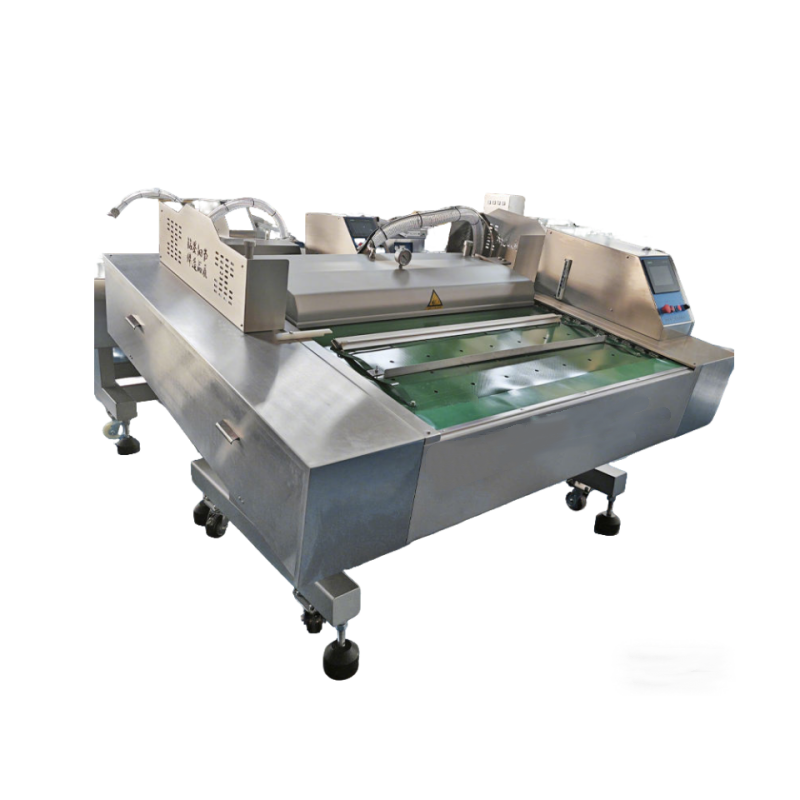

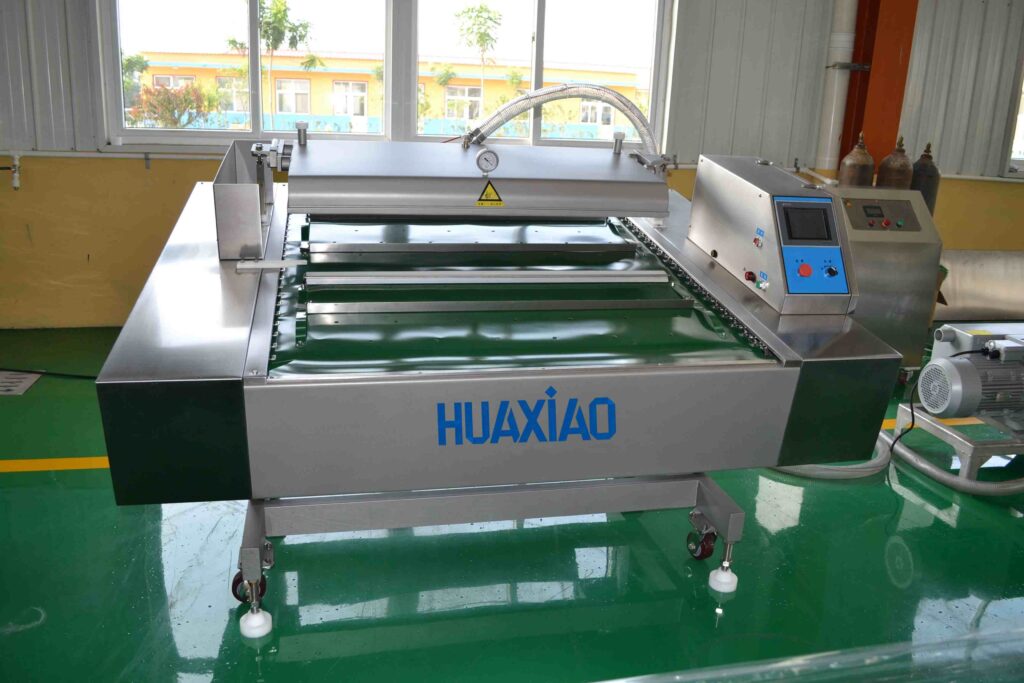

HX-1000 Stainless Steel Rolling Vacuum Packaging Machine

Continuous Vacuum Packing Machine

- Non-Stop Continuous Production: 5X Higher Output Than Batch Models

- 240-300Bags/Min: Adjustable speed fits your production line perfectly

- Fully Automated Workflow: Feed → Vacuum → Seal → Discharge, no manual halt

- FDA & HACCP Certified: Food-grade 304 stainless steel for safe processing

- Cut Labor by 80%: Only 1–2 operators needed for 24/7 running

Description

HX-1000 Automatic Rolling Vacuum Packaging Machine

Rolling Vacuum Packaging Machine For Meat/Seafood/Vegetables

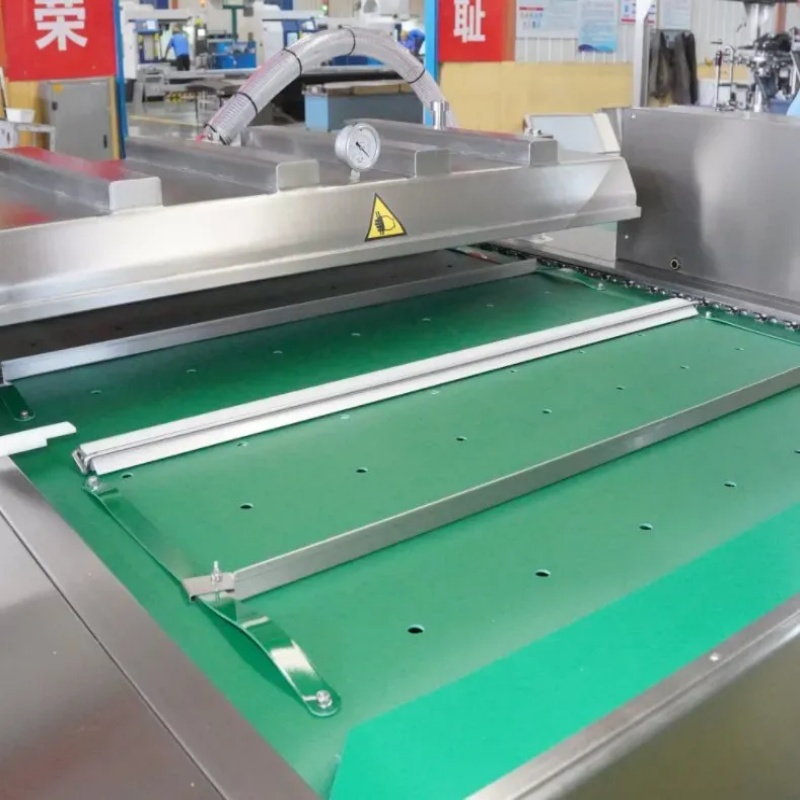

A Rolling Vacuum Packaging Machine (also called continuous rolling vacuum sealer) is an industrial-grade packaging solution engineered for high-volume, automated production lines—designed to seal products in airtight vacuum packaging through a continuous rolling conveyor system. Equipped with PLC control and a durable tilting table option, this 304 stainless steel rolling vacuum machine eliminates manual intervention, making it a core component of modern automatic rolling vacuum packaging lines. Unlike batch-type vacuum machines that require manual loading/unloading between cycles, this equipment enables non-stop workflow: automatic feeding, vacuum extraction, heat sealing, and discharging—critical for B2B buyers in food processing, pharmaceuticals, electronics, and hardware seeking to scale production efficiency while preserving product quality. As a trusted rolling vacuum packaging machine manufacturer, we offer custom quotes for bulk orders, tailored to your production line specifications.

Technical Parameter

| Model | HX1000-1 | HX1000-2 | HX1100-1 | HX1100-2 |

|---|---|---|---|---|

| Voltage | 3P-380V/50HZ | 3P-380V/50HZ | 3P-380V/50HZ | 3P-380V/50HZ |

| Pressure | 0.1-0.5 Mbr | 0.1-0.5 Mbr | 0.1-0.5 Mbr | 0.1-0.5 Mbr |

| Pumping Rate | 80-120 L/S | 80-120 L/S | 80-120 L/S | 80-120 L/S |

| Vacuum Chamber | 1125*440*110 MM | 1125*440*110 MM | 1225*580*110 MM | 1225*580*110 MM |

| Seal Length | 1000*10 MM | 1000*10 MM | 1000*10 MM | 1000*10 MM |

| Heat Seal | 1 | 2 | 1 | 2 |

| Capacity | 240-360 Times/H | 240-360 Times/H | 240-360 Times/H | 240-360 Times/H |

| Dimension | 1800*1400*1000 MM | 1800*1400*1000 MM | 1900*1620*1400mm | 1900*1620*1400mm |

| Weight | 450KG | 450KG | 560KG | 560KG |

Core Benefit

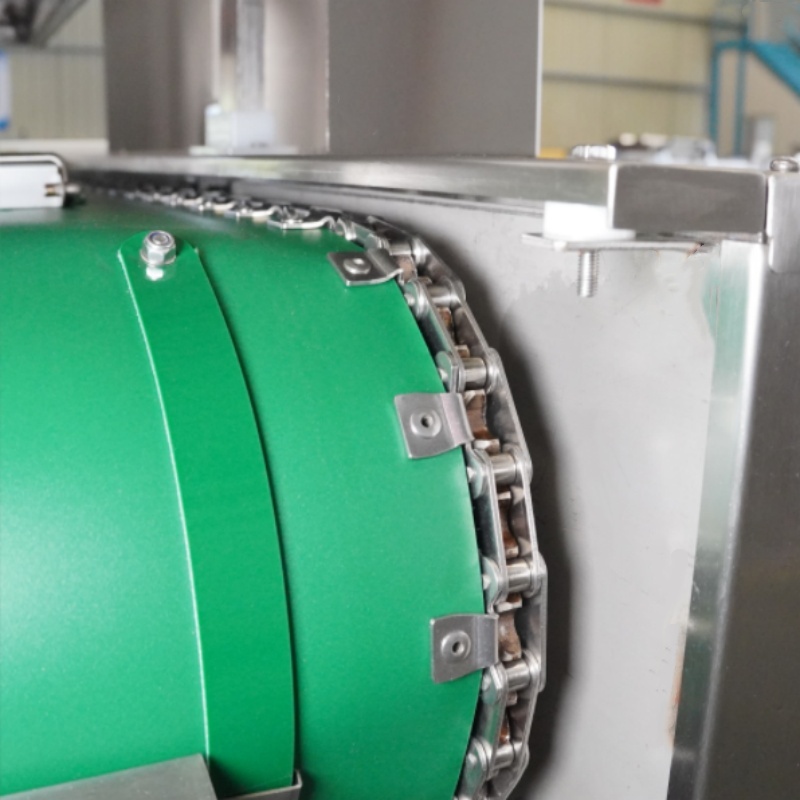

· Whole machine frame is constructed by high grade SUS 304

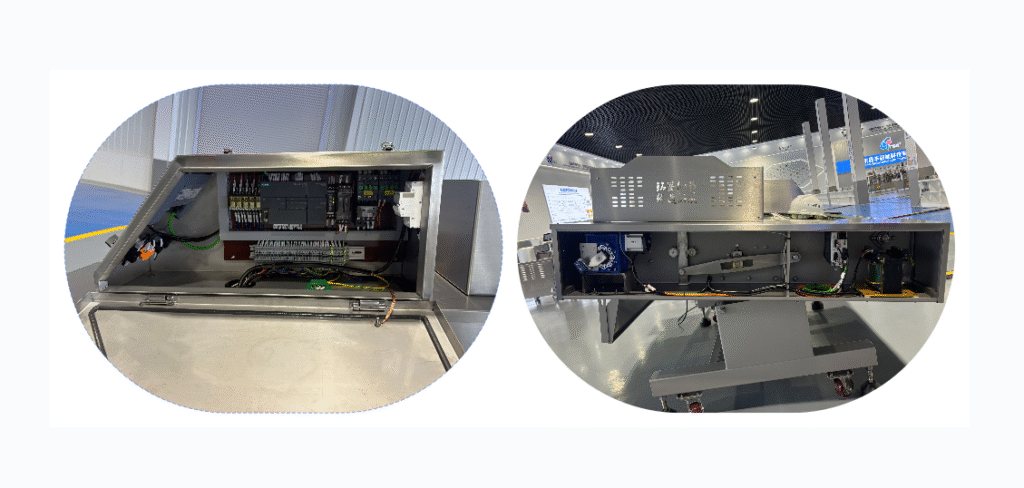

· Advanced electronic components and PLC systems, waterproof grade IP65.

· Independent R&D and strong ductility heat strips, which has a certain degree of scalability to prevent folding, 3 time lifetime than others.

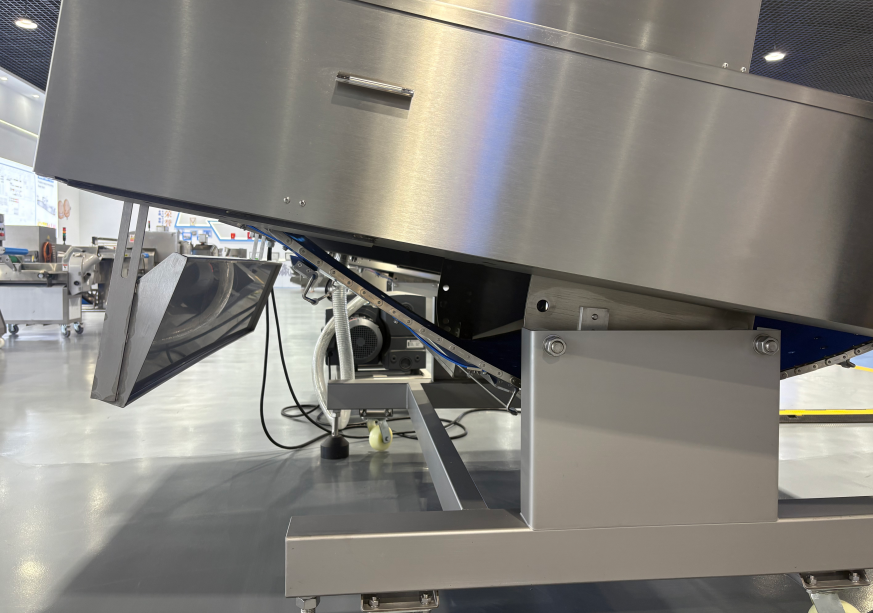

· whole machine can be tilted at five angles to achieve 0-30 degrees sealing angle

Product Application

Meat products:

pork, beef, steak, meatloaf, hamburger, lion, ribs, venison, sausage, ham, bacon, meatballs, grill, bacon, minced meat

Poultry products:

whole chicken, chicken breast, duck, eggs, chicken wings, chicken legs, quail Fish and seafood products: fish fillets, mackerel, farmed fish, salmon, tuna, fish balls, shrimp, lobster tail, oysters, octopus, mussels

Dairy:

Cheese blocks, cheese blocks, cheese blocks

Vegetables and fruits:

frozen durian, frozen potatoes, frozen carrots, bamboo shoots, asparagus, lettuce, olives, pickles

The machine is also an ideal equipment for vacuum packaging of non-food products, such as medical devices, laboratory equipment, auto parts, high-precision machine parts, etc., providing a safe, dry, hygienic and rust-proof storage environment for these products.