Description

Semi-Automatic Modified Atmosphere Packing Machine – Food-Grade Gas Flush Packer

Semi-Automatic MAP Packaging Machine for Meat/Seafood with PLC Control

Semi-Automatic Modified Atmosphere Packaging Machine (also called semi-auto gas flush packer) is an industrial-grade solution designed for food, medical, and deli industries—replacing air in pre-made bags/containers with a precise mix of protective gases (CO₂, N₂, O₂) to extend shelf life, inhibit microbial growth, and preserve product freshness. Unlike fully automated lines (high MOQ) or manual packing (low efficiency), this semi-auto model balances flexibility and productivity, requiring only 1-2 operators for feeding/sealing—ideal for medium-to-large factories, food processors, and distributors scaling their operations.

Technical Parameter

| Model | MAP-410 | MAP-410 G2 | MAP-460 | MAP-460 G2 |

| Film Width mm | 410 | 410 | 460 | 460 |

| Effective size mm | 580*410 | 580*410 | 580*460 | 580*460 |

| Compressed air | 0.6-0.8Mpa | 0.6-0.8Mpa | 0.6-0.8Mpa | 0.6-0.8Mpa |

| Weight kg | 360 | 450 | 400 | 480 |

| Power Voltage | 380/50 or Customized | 380/50 or Customized | 380/50 or Customized | 380/50 or Customized |

| Speed(cycles/min) | MAP 3-4

SKIN 2-3 | MAP 3-4

SKIN 2-3 | MAP 3-4

SKIN 2-3 | MAP 3-4

SKIN 2-3 |

| Gas displacement accuracy | ≥99.0% | ≥99.0% | ≥99.0% | ≥99.0% |

Product Advantage

- Multi-Scenario Adaptability: Compatible with all types of food trays/boxes, and works seamlessly with composite films, regular packaging films, anti-fog films, and other material substrates. Perfect for packaging snacks, prepared meals, fresh produce, baked goods, and more.

- Full-Automatic Workflow: From automatic nitrogen filling (extending shelf life by preventing oxidation) to precise sealing, clean cutting, and finished product collection, the entire process requires minimal manual intervention. It achieves a high packaging yield of up to 1200+ boxes per hour, easily handling peak-season orders.

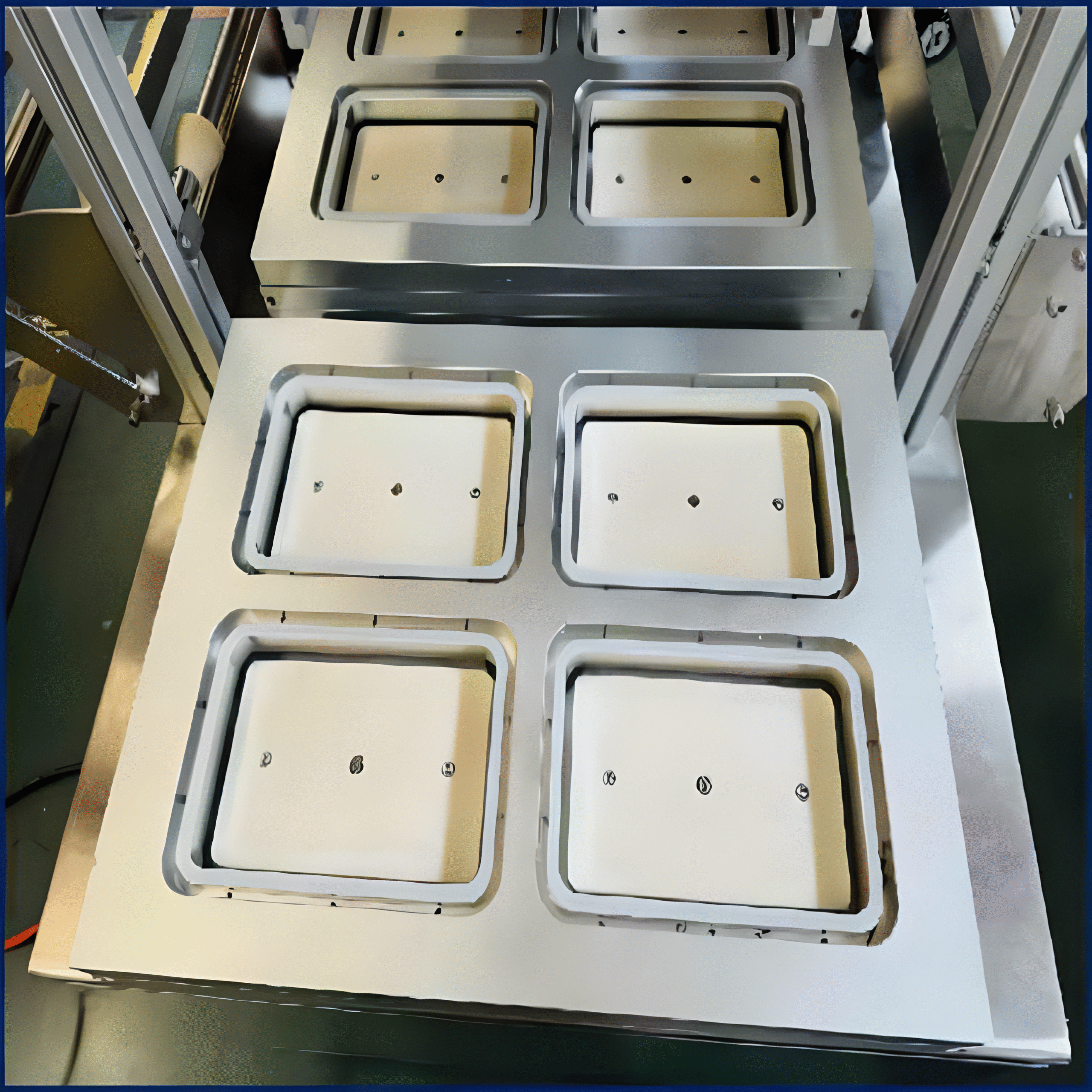

- Customizable Molding Options: Molds can be tailored to your specific packaging styles—whether standard rectangles, irregular shapes, or unique tray sizes. Quickly switch between product lines with tool-free mold changes, supporting flexible small-batch and multi-variety production.

- PLC Touch Screen Operation: Equipped with a programmable logic controller (PLC) and intuitive human-machine interface (HMI). All operational parameters (sealing actions, speed, etc.) can be set, modified, and stored directly on the touch screen—no professional technical skills required.

- Precision Parameter Regulation: Heat sealing temperature and time are controlled with high accuracy (temperature error ≤±1℃), ensuring airtight, wrinkle-free seals that pass leakage tests. The stable sealing effect safeguards product freshness and avoids waste from defective packaging.

- Low Failure & High Durability: Industrial-grade core components and modular design minimize downtime, while the fully automated process reduces human error. This translates to lower maintenance costs and a longer equipment service life.

Why B2B Buyers Choose This Machine

-

- Cost Efficiency: Reduces labor requirements by 60% compared to manual packaging, cutting long-term operational expenses while boosting throughput.

- Compliance & Safety: Constructed with food-grade materials (304 stainless steel contact parts) to meet global food hygiene standards, ensuring product safety and regulatory compliance.

- Scalability Support: Adapts to growing production needs—whether you’re scaling up output or expanding product lines, the machine’s flexibility eliminates the need for frequent equipment replacements.

Product Application

Meat and sausage products Red meat (beef, pork):

With high O₂ (70–80%) to maintain bright red color, CO₂ (20–30%) inhibits microorganisms.

Poultry: High CO₂ (50%) extends shelf life, combined with cold chain. Smoked/cured meat products: Low CO₂ (<20%) prevents the development of sour taste and extends shelf life.

Aquatic products Fish/seafood:

CO₂ (50%) delays spoilage, N₂ prevents packaging collapse. Shellfish/crustaceans: Low CO₂ (20–30%) prevents sour taste from developing.

Dairy products Hard cheese: CO₂ inhibits mold without interfering with the ripening process. Soft cheese/yogurt: Low CO₂ (<20%) prevents packaging collapse and the onset of sour taste.

Fruits, vegetables, and ready-to-eat products Fresh fruits and vegetables:

Uses EMA (balanced atmosphere) combined with micro-perforated film to maintain the O₂ required for respiration. Ready-to-eat meals/salads: A mixture of CO₂ and N₂ inhibits bacteria and extends shelf life.

Baking and snacks Bread/cake:

A CO₂-rich atmosphere prevents mold, and N₂ prevents collapse. Nuts/potato chips: 100% N₂ prevents oxidation and mechanical damage.

Other high value-added products Coffee/milk powder:

Pure N₂ packaging prevents fatty acid oxidation.

Wine:

Inert gas (Ar, N₂) protects the headspace of the bottle to avoid oxidation and deterioration

Our Factory

Our Certificate

FAQ

A:We offer full-cycle customization to match your production needs:

- Core customizations: Mold shapes/sizes (for different food trays/boxes), gas mixture ratios (CO₂/N₂/O₂ for snacks, fresh produce, prepared meals, etc.), and sealing parameters (adjustable for composite/anti-fog/regular films).

- Lead time: Standard molds take 7-10 working days; non-standard or complex designs require 15-20 working days. We’ll provide a detailed customization plan within 24 hours of receiving your product specifications.

- MOQ: 1 unit (supports small-batch trial orders for new clients).

- Payment terms: Flexible options tailored for global trade—T/T (30% deposit + 70% balance before shipment), L/C at sight (Letter of Credit), and Western Union. For repeat clients, we offer favorable terms like D/P (Documents against Payment) after mutual verification.

- Shipping & logistics: We cooperate with leading freight forwarders (DHL, FedEx, Maersk, etc.) to offer door-to-door (DDP/DDU) or port-to-port (CIF/FOB) services. The machine is packed in wooden crates with moisture-proof and shockproof treatment to avoid damage during transit.

- After-sales support:

✅ 1-year warranty for core components (PLC, sealing system, gas mixer).

✅ Free online technical support (24/7 via video call, email, or WhatsApp).

✅ On-site service available (engineer dispatch within 5-7 working days) with cost transparency (airfare + accommodation + service fee quoted in advance).

✅ Free spare parts kit included (sealing strips, sensors, etc.) for quick replacements.

- Compliance: The machine is CE-certified (meets EU safety standards) and constructed with food-grade 304 stainless steel (compliant with FDA/ISO 22000). It adheres to electrical safety standards (IP54 protection grade) for global use.

- Customs documents: We provide a full set of documents including Commercial Invoice, Packing List, Bill of Lading, Certificate of Origin (CO), CE Certificate, and Quality Inspection Report—all tailored to your target market’s customs requirements (e.g., EUR1 for EU, Form A for developing countries).

- Production lead time: 15-20 working days for standard machines; 25-30 working days for customized models (includes production, testing, and packaging).

- Order process:

- You provide product details (packaging size, food type, film material, customization needs).

- We send a tailored quote, technical proposal, and video demo (if requested) within 48 hours.

- After confirmation, you pay the deposit (30% of total amount).

- We start production and send weekly progress updates (with photos/videos).

- Pre-shipment inspection: You can arrange an on-site inspection or request a video inspection to confirm quality.

- You pay the balance, and we ship the machine with full documents.

- We provide installation guidance and operational training via video after delivery.