In the global food supply chain, prolonging food freshness while preserving quality remains a critical challenge for manufacturers, retailers, and exporters alike. Vacuum sealing has emerged as a time-tested solution, transforming food preservation through scientific principles and cutting-edge technology. For international buyers who prioritize technical specifications, certification standards, and cost-efficiency, understanding the mechanics of vacuum packaging and selecting the right solutions is pivotal to optimizing supply chain performance and minimizing product waste.

The Science Behind Vacuum Packaging’s Shelf Life Extension

Vacuum sealing extends food storage duration primarily by targeting three core causes of spoilage: oxygen exposure, microbial proliferation, and moisture loss. By extracting air from the packaging environment—typically achieving a vacuum degree of -98kPa or higher—this technology creates an airtight barrier that inhibits the growth of aerobic bacteria, mold, and yeast. For instance, fresh meat sealed with a high-barrier vacuum film (120μm or thicker) can maintain freshness 3-5 times longer than traditionally packaged alternatives, as oxygen levels are reduced to below 2%—the threshold for most spoilage-causing organisms.

Beyond oxygen removal, vacuum sealing minimizes moisture loss, preserving the texture and juiciness of perishables like seafood, fruits, and baked goods. When combined with modified atmosphere packaging (MAP) or oxygen scavengers, the preservation effect is further amplified—making it an ideal choice for long-distance delivery and international shipping. This scientific mechanism explains why vacuum-packed solutions have become indispensable in global food trade, particularly for cross-border e-commerce and industrial-scale food processing operations.

Key Technical Parameters for Optimal Performance

For global purchasers focused on technical excellence, specific parameters directly influence the effectiveness of vacuum packaging in extending shelf life:

- Vacuum Degree: Industrial vacuum packaging machines with a vacuum degree ranging from -98kPa to -100kPa are recommended for high-risk foods such as meat and seafood, as they eliminate nearly all residual oxygen. Smaller enterprises may opt for commercial vacuum sealers with a -95kPa vacuum degree to balance performance and cost-efficiency.

- Film Thickness & Barrier Properties: Puncture-resistant vacuum film with a thickness of 100-150μm provides superior protection against physical damage during transit. High-barrier materials—such as EVOH-coated films—prevent gas permeation, ensuring long-term freshness for sensitive products.

- Sealing Efficiency: Automatic vacuum sealers with a production capacity of 50-60pcs/min are well-suited for medium to large food factories, while small bakeries or farms may prefer semi-automatic models for greater flexibility. Heat-sealable vacuum pouches designed for a sealing temperature range of 120-180℃ guarantee airtight closure, preventing oxygen re-entry.

- Advanced Technologies: Vacuum skin packaging (VSP) is gaining traction for fresh produce, as it adheres tightly to the food surface to reduce oxidation and maintain visual appeal. For eco-conscious markets, BPI-certified compostable vacuum film offers a sustainable alternative without compromising preservation performance.

Certification Standards: Ensuring Safety and Compliance

Global buyers prioritize certification standards to meet regional regulatory requirements and build consumer trust. The most recognized certifications in the industry include:

- Food Safety Certifications: FDA-approved vacuum packaging materials and LFGB-compliant vacuum sealers are mandatory for market access in North America and Europe, ensuring products are free from harmful substances like BPA.

- Quality Management Certifications: ISO 9001-certified vacuum packaging machines guarantee consistent performance and reliable after-sales support—a key consideration for bulk procurement.

- Third-Party Testing: SGS-tested vacuum packaging for food provides independent verification of shelf life claims, helping buyers avoid costly product recalls and compliance issues.

For exporters, selecting certified products not only ensures regulatory compliance but also enhances competitiveness in overseas markets, where consumers increasingly value safety, transparency, and adherence to global standards.

Application Scenarios Across Global Markets

The versatility of vacuum packaging makes it suitable for diverse industries and regional markets:

- Meat & Seafood Processing: In countries like the US, Australia, and Japan, 1000W commercial vacuum sealers with 2.5bar pressure are widely used in meat processing plants, extending the shelf life of beef, pork, and seafood from days to weeks.

- Restaurant & Catering: European restaurants rely on vacuum food storage systems to minimize food waste, with vacuum-sealed takeaway becoming a post-pandemic standard to maintain quality during delivery.

- Cross-Border E-Commerce: For Chinese exporters selling snacks, dried fruits, or baked goods to Southeast Asia, high-barrier, puncture-resistant vacuum packaging for international shipping prevents spoilage during long-distance transit in humid conditions.

- Small Businesses & Farms: Vacuum-packed produce directly from farms is popular in organic markets across Europe and North America, with compact vacuum packaging equipment for small bakeries enabling artisanal producers to expand their market reach.

Choosing the Right Vacuum Packaging Solution

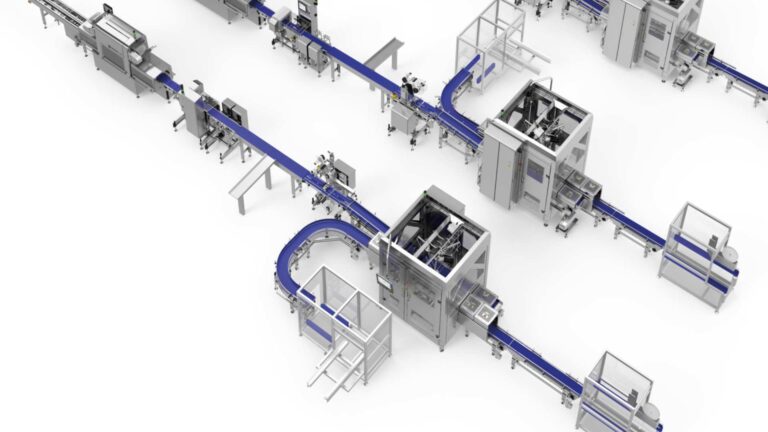

When selecting vacuum packaging products, global buyers should adhere to a priority framework: technical parameters > certification standards > price. For industrial applications, investing in large-scale industrial vacuum packaging lines with CE certification and high production capacity delivers long-term value. For small to medium-sized enterprises, cost-effective commercial vacuum packaging machines under $5000 with FDA approval strike the optimal balance between performance and budget.

For packaging materials, prioritize food-grade vacuum bags with high barrier properties for perishables, while affordable bulk vacuum packaging bags are suitable for non-perishables like nuts or dried herbs. Always verify certification documents and request sample testing to ensure products align with the specific requirements of your target market.

Conclusion

Vacuum packaging is a transformative solution for extending food shelf life, driven by its scientific design and continuous technical advancements. For global buyers, focusing on key technical parameters—such as vacuum degree, film thickness, and sealing efficiency—ensures optimal preservation performance, while adherence to international certification standards guarantees compliance and consumer trust. By aligning solutions with application scenarios across target markets and following a data-driven purchasing framework, businesses can leverage vacuum packaging to enhance supply chain resilience, reduce waste, and expand their global footprint.

Whether you’re a large food manufacturer or a small-scale exporter, choosing the right vacuum packaging solution—backed by robust technical specifications and recognized certifications—will unlock new opportunities in the competitive global food market.