Mini Thermoforming Stretch Film Vacuum Packaging Machine

Automatic Industrial-Grade Food & Product Sealing Equipment

1.Full automation integrates thermoforming, vacuuming, sealing, cutting and coding in one cycle.

2.High efficiency food packaging machine 30-120 packs per minute

3.Versatile food packaging machine for solid, liquid, powder & irregular products

4.Food safety compliance with FDA/CE-certified food-grade films (PE, PP, PA composite films) and 304 stainless steel cover surfaces.

5.High-efficiency versatile food packaging machine (30-120 packs/min, 5-80mm forming depth)

Description

Thermoforming Vacuum Packaging Machine for Meat/Seafood/Poultry

High – Speed Thermoforming Vacuum Packaging Machine

A thermoforming vacuum packaging machine (also called a rollstock thermoforming machine) is a fully automated packaging system that uses heat, pressure, and vacuum to turn flat plastic roll film into custom – shaped, airtight packages for high – volume production. It eliminates the need for pre – made bags, completing forming, filling, vacuum/MAP (modified atmosphere packaging) sealing, and cutting in one continuous cycle, which is a game – changer for food, medical, and industrial sectors aiming for efficiency and product freshness.

Technical Parameter

| Model | HX-320 | HX-420 | HX-520 | HX-680 |

|---|---|---|---|---|

| Power | 7KW | 10KW | 12KW | 16KW |

| Base film width | 322mm | 422mm | 522mm | 680mm |

| Top film width | 295mm | 395mm | 495mm | 661mm |

| Voltage | 380V 50Hz | 380V 50Hz | 380V 50Hz | 380V 50Hz |

| Machine Dimension | 4500*800*1750mm | 5500*900*1750mm | 7500*1000*1750mm | 6500*1400*1800mm |

| Weight | 1200KG | 1800KG | 2200KG | 2400KG |

| Packing speed | 4-7 times/min | 5-7 times/min | 5-7 times/min | 3-6 times/min |

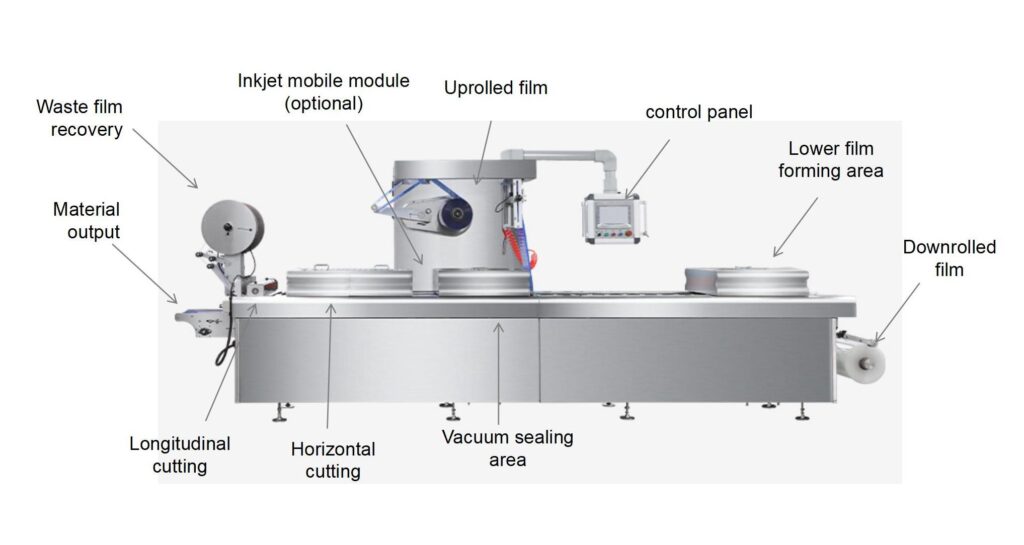

Composition Structure

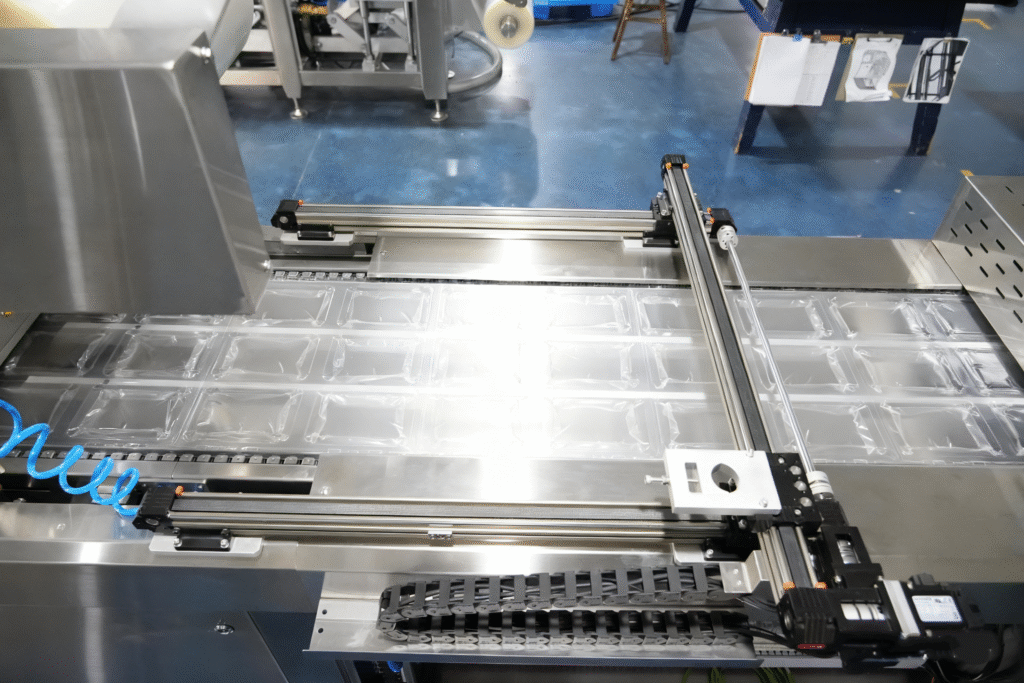

- Thermoforming System: Includes heating plates and temperature control modules, adjustable to 0-280℃ for different film materials.

- Vacuum System: High-power vacuum pump and airtight chamber, supporting optional gas flushing (N₂/CO₂) for modified atmosphere packaging.

- Sealing & Cutting System: Dual-temperature control heating bars for tight seals, and precision cutting tools for neat edges.

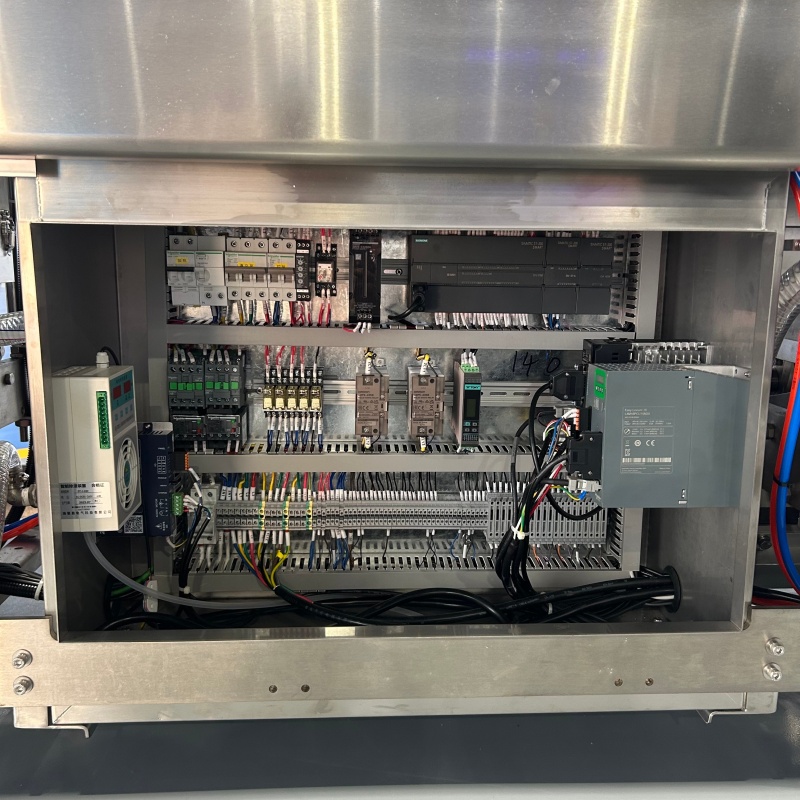

- Control System: PLC touchscreen with programmable settings, enabling quick parameter adjustment for different products.

- Frame & Conveyor: 304 stainless steel structure for corrosion resistance, plus a conveyor belt for continuous operation.

Product Advantage

High Efficiency & Full Automation

One-key start for integrated processes: thermoforming, vacuuming, sealing, cutting, and coding.

30-60 packs per minute output, 3x more efficient than semi-automatic models.

Continuous operation design reduces manual intervention and waiting time.

Precision Thermoforming & Sealing

Customizable forming depth (5-50mm) adapts to various product shapes and sizes.

Double heating zones with temperature control (0-250℃) ensure tight, wrinkle-free seals.

Food-grade stretch film compatibility (PE, PP, PA composite films) meets safety standards.

Stable Performance & Durability

304 stainless steel frame and working chamber for corrosion resistance and easy cleaning.

High-power vacuum pump (1500W) achieves 0.098MPa vacuum degree for long-term preservation.

PLC touchscreen control with 100+ storage programs for quick parameter adjustment.

Multifunctional Application

Suitable for solid, liquid, powder, and irregular products.

Ideal for food industry (meat, seafood, fruits, snacks), medical supplies, electronics, and hardware.

Supports vacuum packaging, gas-flushing packaging (N₂/CO₂), and modified atmosphere packaging (MAP).

Application

Food Industry: Vacuum packaging for fresh meat, frozen seafood, dried fruits, cooked food, and ready-to-eat meals to extend shelf life by 3-5 times.

Medical & Pharmaceutical: Sterile packaging for medical devices, masks, and drugs to prevent contamination.

Electronics & Hardware: Moisture-proof packaging for electronic components, screws, and tools to avoid oxidation.

Daily Chemicals: Sealed packaging for cosmetics, toiletries, and detergents to preserve efficacy.

Our Factory

Our Certificate

FAQ

Q: What products can this machine package? And what films are compatible?

A:It works for solids, liquids, powders and irregular-shaped items—like fresh meat, seafood, medical devices, electronic components. For films, food-grade PE, PP, PA and composite films are all compatible, fully FDA/CE certified, safe and reliable.

Q: How much more efficient is it than semi-automatic models?

A:Full automation in one go: thermoforming, vacuuming, sealing, cutting and coding are completed together, with 30-120 packs per minute. No manual waiting between processes, directly saving 60% labor costs—super convenient for mass production.

Q: Besides vacuum packaging, can it do Modified Atmosphere Packaging (MAP)?

A:Absolutely! It can both vacuum for oxygen-free preservation and fill with nitrogen/carbon dioxide for MAP. Food shelf life can be extended 3-5 times, and electronic/medical products can be stored for 1-3 years—excellent freshness and moisture-proof effects.

Q: Is after-sales and maintenance guaranteed?

A:Core components (vacuum pump, heating system, PLC controller) come with a 1-year warranty, and 24/7 technical support is available anytime. On-site installation and training are also provided, and spare parts are easy to get—basically no production delays.

Q: Can it adapt to local voltage? Are there export certifications?

A:Voltage can be customized: 110V/60Hz (North America), 220V/50Hz, 380V/50Hz are all available. It has full certifications including CE, FDA and ISO, which meets import requirements for markets like North America, Europe and Southeast Asia.

Q: Can it be customized for our product sizes?

A:Definitely! Forming depth is adjustable from 5-80mm, and film width and forming area can also be customized. Special needs like large irregular items and high-liquid foods can all get tailored solutions.