Ultimate Purchasing Guide for Argentine Sandwich, Pizza & Beef Food Manufacturing Facilities

Compliance, Freshness Preservation & Production Capacity Optimization

Executive Overview

For Argentine food manufacturing facilities specializing in sandwich, pizza, and beef products, procurement decisions are pivotal to operational efficiency, product integrity, and regulatory adherence. Operating within Argentina’s stringent regulatory landscape—characterized by rigorous food safety protocols, import/export mandates, and sector-specific operational demands—procurement requires a strategic framework centered on industry-specific scenario alignment, Argentine regulatory compliance, and best-in-class purchasing practices. This guide is engineered to address core operational imperatives: maintaining optimal freshness throughout the supply chain, scaling production capacity sustainably, and upholding non-negotiable compliance standards—critical for competitiveness in both domestic and regional markets (e.g., Mercosur, EU export corridors).

1. Industry-Specific Scenario Alignment: Procurement Tailored to Production Paradigms

Argentine sandwich, pizza, and beef manufacturing facilities span diverse operational spectra—from artisanal micro-factories serving hyperlocal markets in Buenos Aires to large-scale industrial complexes supplying national retail networks and international distribution channels. Procurement strategies must be meticulously calibrated to these operational contexts to mitigate bottlenecks, ensure quality consistency, and optimize cost structures.

1.1 Targeted Procurement for Specialized Product Lines

Beef Processing Facilities

As a global leader in beef production, Argentina’s processing facilities must prioritize procurement that preserves the intrinsic quality of Argentine beef. Key considerations include:

- Industrial-grade refrigeration infrastructure (walk-in cold storage units, blast chillers) with precise temperature regulation (-18°C for frozen cuts, 0-4°C for chilled beef) to mitigate freezer burn and microbial proliferation.

- Precision meat processing equipment: adjustable-plate meat grinders (for variable particle size applications) and vacuum tumblers for marination—enhancing flavor infusion while extending shelf life through modified atmosphere processing (MAP) compatibility.

- Scalable production systems engineered to accommodate 20-30% excess capacity, aligning with Senasa’s projected 12% annual growth in Argentine beef exports through 2026.

Sandwich & Pizza Manufacturing Plants

High-volume, time-sensitive production environments demand procurement focused on process optimization:

- Commercial-grade dough preparation systems (50-100kg batch mixers, automated dough dividers) to ensure portion uniformity and reduce cycle times.

- Programmable convection ovens with precise temperature modulation (220-250°C for pizza, 180-200°C for sandwiches)—delivering 30% faster cook times versus conventional equipment.

- Pre-portioned, value-added ingredients (sliced charcuterie, shredded dairy products, diced botanicals) to streamline assembly lines, reducing preparation labor by 40% and minimizing food waste.

1.2 Freshness-Centric Sourcing Protocols

Argentina’s geographic expanse and climatic variability present unique cold chain challenges. Mitigate risks through:

- Temperature-controlled logistics solutions equipped with GPS-enabled real-time monitoring systems, ensuring compliance with ANMAT’s cold chain integrity mandates (±2°C fluctuation tolerance).

- Modified Atmosphere Packaging (MAP) machinery—extending the shelf life of ready-to-process sandwich and pizza components from 3-5 days to 10-14 days without synthetic preservatives.

- Locally sourced perishables: Pampas-region beef, Córdoba-origin provolone, and Mendoza-grown produce—reducing transit time by 50-70% and lowering spoilage rates (imported perishables typically incur 8-10% wastage in Argentina).

2. Argentine Regulatory Compliance: Mandatory Frameworks for Procurement

Argentina’s food safety regulatory regime—administered by ANMAT (National Administration of Drugs, Food and Medical Technology) and Senasa (National Service of Agri-Food Health and Quality)—ranks among the most rigorous in Latin America. Non-compliance carries severe consequences, including pecuniary penalties (up to ARS 5 million ≈USD 15,000), operational shutdowns, or permanent export restrictions. Procurement must be anchored in regulatory adherence.

2.1 Core Compliance Mandates

Food Safety Certifications

- Mandatory compliance with ISO 22000 (food safety management systems) and HACCP (hazard analysis and critical control points) for all equipment, ingredients, and packaging materials.

- Senasa’s “Certificación de Calidad” (Quality Certification) for beef suppliers—requiring end-to-end traceability from livestock production to processing, including breed documentation, feed source verification, and slaughterhouse audit records.

- ANMAT’s “Registro de Establecimiento Alimentario” (Food Establishment Registration) as a prerequisite for procuring production equipment.

Packaging Regulations (2021 Plastic Waste Legislation)

- 60% of food contact packaging must be recyclable, compostable, or biodegradable by 2025—mandating compostable paper-based wraps for sandwiches/pizza and recyclable vacuum-sealed films for beef products.

- Mandatory labeling requirements:

- Bilingual (Spanish-English) ingredient declarations in descending order of weight.

- Nutritional profiling (per 100g/ml) and allergen disclosures (gluten, dairy, soy, nuts).

- Expiration dating (DD/MM/YYYY format) and valid Senasa/ANMAT registration identifiers.

Import/Export Compliance Protocols

For procuring foreign-sourced equipment or ingredients:

- ANMAT import authorization (processing timeline: 4-6 weeks) with documented product safety validation.

- Senasa sanitary certification for food-grade equipment and ingredients.

- Compliance with Argentine electrical standards (220V, 50Hz) to ensure operational safety and equipment longevity.

2.2 Compliance-Focused Procurement Strategies

- Mandate Certificate of Conformity (CoC) and third-party laboratory test reports from suppliers, verifying alignment with Argentine regulatory benchmarks.

- Prioritize vendors with a domestic presence (Buenos Aires, Rosario, Córdoba)—facilitating expedited documentation processing, on-site technical training, and regulatory liaison support.

- Implement annual supplier compliance audits to align with evolving Senasa/ANMAT standards and amendments to food safety legislation.

3. Strategic Purchasing Imperatives: Optimizing Capacity, Cost, and Reliability

Procurement for Argentine food manufacturing facilities constitutes a long-term capital investment, requiring a holistic approach to capacity optimization, cost efficiency, and supplier resilience.

3.1 Production Capacity Optimization

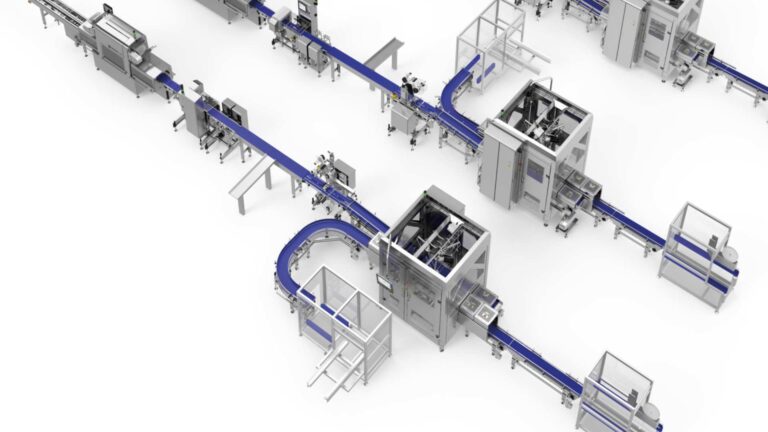

- Modular Equipment Solutions: Invest in scalable, modular systems (e.g., expandable packaging conveyors, configurable cold storage units) to avoid capital-intensive full replacements—delivering 30-40% savings in capital expenditure over a 5-year lifecycle.

- Automation Integration: Deploy robotic assembly systems for sandwiches, automated topping dispensers for pizza, and precision portioning machinery for beef—reducing labor costs (which account for 25-30% of operational overhead) and increasing throughput by 50-60%.

- Energy Efficiency Compliance: Source equipment certified by ENERGY STAR or INEN (National Institute of Standardization)—energy-efficient refrigeration systems reduce electricity consumption by 30%, translating to monthly savings of ARS 20,000-30,000 for mid-sized facilities.

3.2 Cost-Optimized Sourcing

- Bulk Procurement with Flexible Terms: Negotiate volume discounts for staple commodities (flour, edible oils, seasonings) and disposable inputs (packaging, sanitization supplies)—leverage 30-60 day payment terms to mitigate cash flow volatility amid Argentina’s inflationary environment.

- Total Cost of Ownership (TCO) Analysis: Evaluate procurement decisions based on lifecycle costs (upfront capital, maintenance, energy consumption, replacement cycles) rather than initial price point—durable, premium-grade equipment (20% higher upfront cost) typically delivers 10-year lifespans with minimal maintenance requirements.

- Collective Purchasing Alliances: Participate in industry consortia (e.g., CAMARA DE INDUSTRIAS ALIMENTARIAS DE ARGENTINA) to access aggregated buying power, securing 15-20% discounts on equipment and ingredients.

3.3 Supplier Reliability & Resilience

- Domestic After-Sales Support: Prioritize suppliers with established service centers in Argentina—ensuring 24-48 hour response times for technical support and repairs, mitigating production downtime (valued at ARS 100,000-200,000 for mid-sized facilities per outage).

- End-to-End Traceability: Mandate comprehensive traceability systems from suppliers, including batch coding, farm-to-factory documentation, and inspection records—critical for regulatory compliance and brand protection during product recalls.

- Strategic Supplier Partnerships: Cultivate long-term relationships with 2-3 tier-1 suppliers per category—securing preferential pricing, priority access to new technologies (e.g., eco-friendly packaging, energy-efficient equipment), and contingency support during supply chain disruptions.

Final Procurement Due Diligence Checklist

- Does the equipment/ingredient align with the facility’s specific production parameters (product type, scale, export focus)?

- Is full compliance with ANMAT, Senasa, ISO 22000, and HACCP standards validated via certified documentation?

- Does the solution enhance freshness preservation (temperature control, packaging compatibility) and reduce spoilage?

- Is the equipment scalable, energy-efficient, and engineered for long-term capacity growth?

- Does the supplier provide domestic after-sales support, regulatory documentation, and flexible payment terms?

- Has a comprehensive Total Cost of Ownership (TCO) analysis been conducted?

Conclusion

By integrating industry-specific scenario alignment, rigorous regulatory compliance, and strategic purchasing principles, Argentine sandwich, pizza, and beef manufacturing facilities can optimize procurement outcomes to drive operational efficiency, safeguard product quality, and enhance market competitiveness. This framework enables facilities to navigate Argentina’s complex regulatory environment, mitigate supply chain risks, and position themselves for sustainable growth in both domestic and international markets.