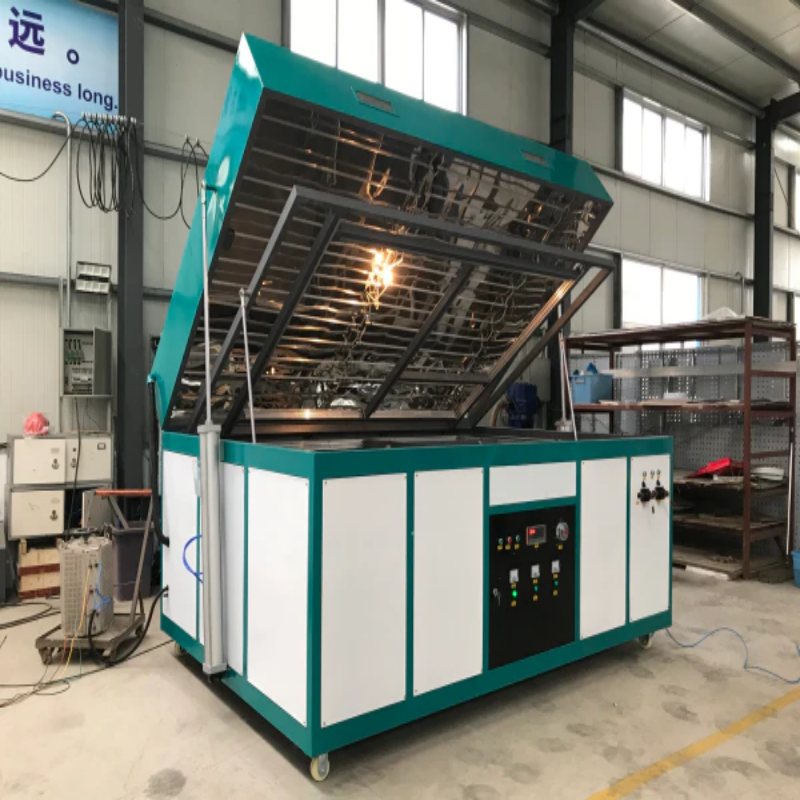

HX-S1224 Vacuum Forming Machine

Industrial Acrylic Vacuum Forming Machine

Description

PVC Film Laminating & Acrylic Vacuum Forming Machine

Acrylic Vacuum Forming Machine PVC Film Laminating Machine on the Door MDF Panel Vacuum Membrane Press Machine

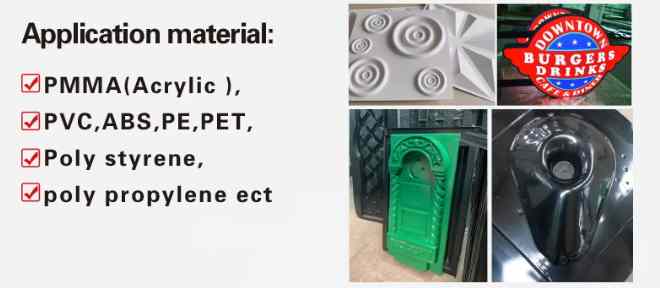

The HX-S-1224 Vacuum Forming Machine is a high-performance thermoforming solution engineered to heat and shape Acrylic, ABS, PVC, PP, PETG, and other thermoplastic materials with precision. Designed to transform flat plastic sheets into intricate 3D designs, this machine has become a trusted asset across diverse industries—including advertising, cosplay prop manufacturing, home decoration, and industrial molding. What sets it apart is its specialized focus on large-scale production, making it the ideal choice for businesses needing to create big thermoforming pieces efficiently and reliably.

Technical Parameter

| Model | HX-S 1224 |

|---|---|

| Working area(mm)(L*W) | 1200*2400 |

| Forming area(mm)(L*W) | 1040*2240 |

| Function | Suction & Blow |

| Max. suction forming depth(mm) | 300 |

| Oven open style | Automatic open |

| Vacuum pump output | 63m³/h |

| Total power(kw) | 20.5 |

| Working Voltage | AC380V/50HZ/3P |

| Net Weight (kgs) | 950 |

| Overall size (mm) (L*W*H) | 2870*1550*1650 |

Details of the machine

Heat oven

1.Factory customized heating rod, which can run 24 hours continuously, offers uniform heating on materials

2.Intelligent temperature control, the heating box adopts heat reflector and thick insulation layer, save considerable energy cost, also has good insulation and safety performance

Lifting platform

1.The machine is equipped with a lifting platform. The platform is controlled by cylinder, which offers stable lifting and could achieve a maximum forming height of 300mm

2.The machine equipped with 63m³/H industrial vacuum pump, ensure great vacuum forming result

Machine structure

1.The main body and frame are made of welded high-quality steel, the thickest part reaching 4mm. Which is durable and great anti-deformation.

2.The paint is made of powder-coated technology, which offers great anti-rust performance and beautiful appearance

Adjustable holding frame

1.The machine equipped with adjustable holding frame, can be used for different sizes material. Reduce considerable materials waste.

2.Both of heat oven and holding frame are controlled by cylinder, just need press button to open it. Very convenient

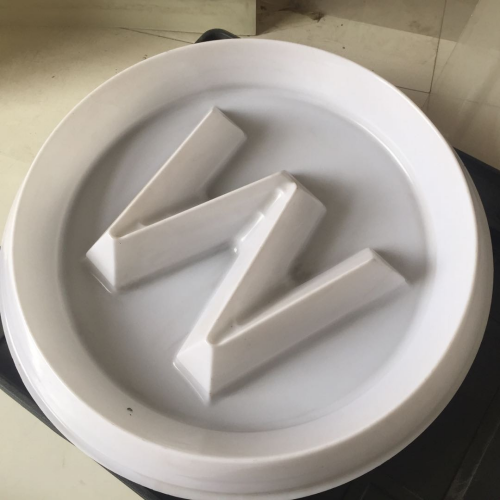

Thermoforming result

1.The machine offers fast vacuum forming and great thermoforming result. can be used for maximum 5mm thickness acrylic and PVC, 6mm on ABS material

2.The machine has blowing function, easy to demold after make vacuum forming, also can be used to make dome design

Core Advantage

1. Intelligent Temperature Control System: Fast Heating & Superior Safety

- Reduces preheating time by 28% compared to standard models, boosting production efficiency

- Complies with EN 60204-1 electrical safety standards, with built-in overheat protection to eliminate fire risks

- Energy-saving design cuts electricity consumption by 15% annually, lowering total operational costs (TOC)

2. Factory-Customized Heater: 24/7 Continuous Operation Reliability

- Ensures uniform plastic sheet softening, reducing product defect rates by 12%

- Eliminates frequent heater replacement downtime, ideal for high-volume manufacturing lines

- Compatible with multi-material processing (PVC, PETG, PP, ABS, PC) across packaging, automotive, and medical industries

3. High-Temperature Resistant Steel Workbench: Cost-Efficient Single-Mold Forming

- Reduces raw material waste by 18% through precise mold alignment

- Simplified operation requires only 1 operator per machine (vs. 3 for traditional models), cutting labor costs by 67%

- Low maintenance design with corrosion-resistant surface treatment, extending platform lifespan to 8+ years

4. Dual-Cylinder Aluminum Alloy Press Frame: Enhanced Sealing & Forming Quality

- Labyrinth-style sealing structure improves airtightness by 3x, ensuring sharp product contours

- Lightweight yet durable aluminum alloy reduces energy consumption during frame movement

- Quick mold changeover (≤30 minutes) supports flexible production of custom parts

5. Dual-Cylinder Movable Platform: Smooth Lifting & Higher Molding Height

- Vertical lifting precision of ±0.1mm, suitable for deep-cavity forming (up to 200mm depth)

- Smooth operation minimizes material deformation, ideal for automotive interior parts and large packaging

- Adjustable height settings accommodate multi-size molds without mechanical modifications

6. High-Power Vacuum Pump: Premium Finished Product Aesthetics

- Vacuum pressure range: -0.07~-0.09MPa, meeting international manufacturing standards

- Rapid vacuum response (≤0.5 seconds) captures fine mold details for high-precision applications

- Compatible with food-grade and medical-grade plastic processing (compliant with FDA requirements)

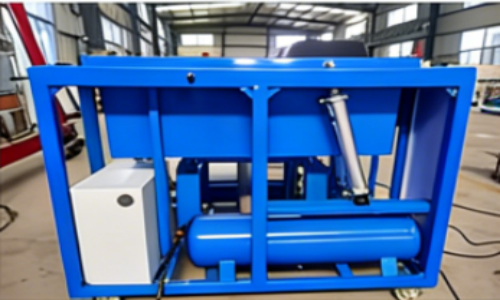

7. Air Storage Tank: Extended Pump Lifespan & Stronger Suction

- Reduces pump load by 30%, extending service life by 50% compared to tank-less models

- Instantaneous suction boost at molding critical points improves forming success rate by 9%

- Low-noise operation (≤75dB) meets workplace safety standards (OSHA/CE)

8. Blowing Function: Easy Demolding & Ball Blow Molding Capability

- Reverse air pressure reduces demolding time by 40%, preventing product damage during removal

- Supports one-step ball forming for toys, medical devices, and packaging components

- Adjustable air pressure (0.65-0.75MPa) adapts to different material thicknesses (0.1-10mm)

Application

Our Workshop

Finished Products