How to Choose a Vacuum Forming Machine: A Guide for Startups and Large – Scale Factories

Introduction: Match Machine to Your Production Reality

Part 1: Startups & Small Businesses – Lean, Flexible, Low-Risk

|

Metric

|

Target Range

|

Rationale

|

|

Monthly Production

|

100–10,000 units

|

Avoid overcapacity; match variable demand

|

|

Budget

|

15,000 |

Preserve capital for marketing/product dev

|

|

Footprint

|

≤1.2m²

|

Fit small workshops/co-working spaces

|

|

Mold Change Time

|

≤20 minutes

|

Adapt to multiple custom designs

|

Top Machine Picks for Startups

- Small Desktop Vacuum Forming Machine

- Ideal For: Prototypes, promotional products (e.g., branded display stands), small-batch blister packs.

- Key Specs: Sheet thickness (0.3–1.5mm), manual/semi-automatic operation, compatible with HIPS/PETG (low-cost materials).

- Pro Move: Choose models with detachable heating elements—they’re easier to store and maintain.

- Keyword Fit: “small desktop vacuum forming machine for custom products” “affordable vacuum forming machine for startups”

- Entry-Level Semi-Automatic Vacuum Forming Machine

- Ideal For: Growing startups (5,000–10,000 units/month) producing food packaging or medical samples.

- Key Specs: Automatic feeding/cooling, sheet thickness (0.5–3mm), basic PLC controls (no technical expertise needed).

- Cost-Benefit: Cuts labor time by 40% vs. desktop models while staying under $15k.

- Keyword Fit: “semi-automatic plastic vacuum forming machine” “entry-level vacuum thermoforming machine”

- Steer clear of fully automatic machines (high upfront cost + idle capacity).

- Reject models without clear technical support (you won’t have an in-house team to troubleshoot).

- Skip machines limited to one material—flexibility is critical for custom orders.

Part 2: Large-Scale Factories – Speed, Consistency, Scalability

|

Metric

|

Target Range

|

Rationale

|

|

Monthly Production

|

20,000–500,000+ units

|

Meet mass-market demand

|

|

Cycle Time

|

≤25 seconds/part

|

Maximize throughput

|

|

Thickness Tolerance

|

±0.1mm

|

Ensure consistent product quality

|

|

Compliance

|

CE/ISO/FDA/GMP

|

Meet global industry standards

|

Top Machine Picks for Large Factories

- Fully Automatic Vacuum Forming Machine

- Ideal For: Mass production of food trays, medical containers, or electronic packaging.

- Key Specs: Automatic feeding/trimming/cooling, sheet thickness (0.5–3mm), speed (20–50 parts/min), PLC with recipe storage (for multiple SKUs).

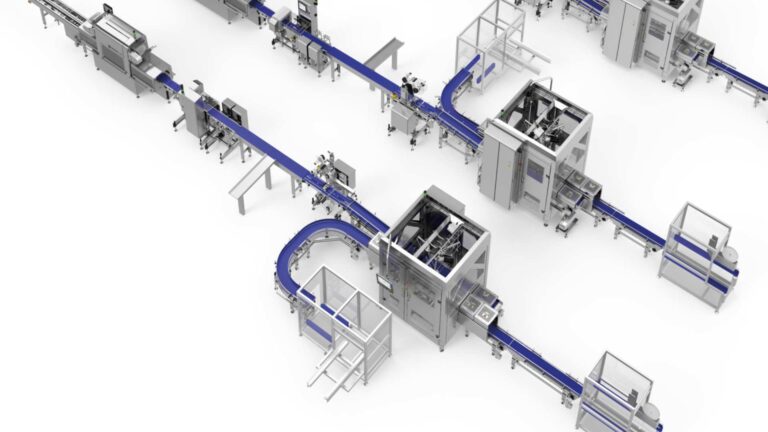

- Must-Have Feature: Integration with robotic stacking systems to reduce labor costs.

- Keyword Fit: “fully automatic vacuum forming machine for food trays” “CE certified vacuum forming machine 0.5-3mm sheet”

- Rotary Vacuum Forming Machine

- Ideal For: Continuous production of automotive components, industrial casings, or large packaging.

- Key Specs: Multi-station design (heating/forming/cooling/trimming), sheet thickness (1–10mm), heavy-duty vacuum pump (≥7.5kW), stainless steel frame.

- Efficiency Boost: 30–50% higher output than standard automatic models (no downtime between cycles).

- Keyword Fit: “rotary vacuum forming machine for automotive parts” “heavy-duty plastic vacuum thermoforming machine”

Factory Must-Ask Questions

- Can it integrate with our existing conveyor belts or quality inspection systems?

- What’s the uptime rate? (Aim for ≥98%—even 1% downtime costs $10k+/month for high-volume lines.)

- Does the manufacturer offer on-site training and 24/7 technical support?

Part 3: Universal Tips for Both Sizes – Avoid Costly Mistakes

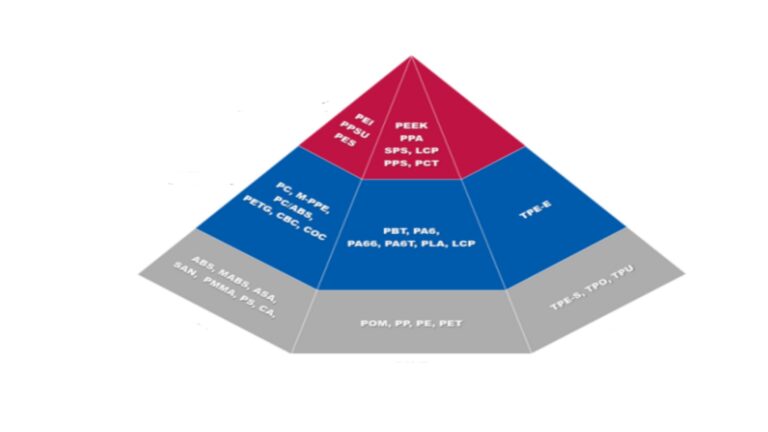

- Test Before You Buy: Request a sample run with your target material (e.g., PP for food trays, ABS for automotive parts) to verify quality.

- Calculate Total Ownership Cost (TOC): Don’t just look at upfront price—factor in energy consumption, mold costs, and maintenance (durable ceramic heating elements save $500+/year in replacements).

- Prioritize Material Compatibility: Ensure the machine handles your core materials (e.g., FDA-approved plastics for food, flame-retardant materials for electronics).

- Plan for Growth: Startups should choose semi-automatic models upgradable to fully automatic; factories need machines with modular designs (add extra stations as demand grows).