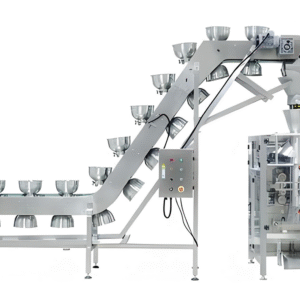

Automatic Multi-function Granular Chips Vertical Form Fill Seal Packaging Machine

Reliable Automatic Vertical Form Fill Seal (VFFS) Packaging Machine

2.Use famous brand electric and pneumatic components, stable and long life circle.

3.Use superior mechanical components, reduce the wear out loss.

4.Easy to install film, auto correcting the excursion of the film.

5.Apply advanced operating system, easy to use and reprogrammable.

Description

Vertical Form Fill and Seal Packaging Machines – Food & Non-Food Solutions

Vertical Form Fill Seal (VFFS) machine for food, powder, liquid packaging

Technical Parameters

Model HXV-420 HXV-520 HXV-620 HXV-730

Packaging Speed 30-60 bags/min 40-80 bags/min 60-100 bags/min 80-120 bags/min

Bag Size Range (L×W) 50-180×30-120mm 60-220×40-150mm 80-280×50-180mm 100-320×60-220mm

Film Width Max 240mm Max 300mm Max 380mm Max 450mm

Material 304 stainless steel 304 stainless steel 304 stainless steel 304 stainless steel

Control System Mitsubishi PLC + HMI touch screen Mitsubishi PLC + HMI touch screen Mitsubishi PLC + HMI touch screen Mitsubishi PLC + HMI touch screen

Film Pulling System Servo motor Servo motor Servo motor Servo motor

Type of bag Back sealing bag Back sealing bag Back sealing bag Back sealing bag

Power Supply Single phase 220v±5% 50~60HZ 2.2~3.9KW Single phase 220v±5% 50~60HZ 2.2~3.9KW Single phase 220v±5% 50~60HZ 2.2~3.9KW Single phase 220v±5% 50~60HZ 2.2~3.9KW

gas consumption 0.8Mps,0.35m³/min 0.8Mps,0.35m³/min 0.8Mps,0.35m³/min 0.8Mps,0.35m³/min

Core Advantage

1. High-Speed Operation: Up to 150 bags per minute, 30% higher than industry average, suitable for large-scale food production.

2. Food-Grade Design: Full stainless steel body, anti-corrosion and easy to clean, complying with FDA, CE, and ISO standards.

3. Intelligent Control: PLC touch screen system, one-click operation, reducing labor cost and error rate.

4. Customizable Solutions: Support bag sizes from 5g to 5kg, adaptable to snacks, grains, frozen food, etc.

Application

Our Certificate

Cooperation Flow

FAQ

1. Q: What certifications do your VFFS packaging machines have, and are they compliant with the regulations of the European and American markets?

A: Our VFFS machines have obtained CE, FDA, ISO9001 and SGS certifications. The food-grade models use 304 stainless steel contact parts, which comply with FDA and EU 10/2011 food contact material regulations; the pharmaceutical-grade models meet GMP standards, fully adapting to the regulatory requirements of European, American and other mainstream markets.

2. Q: Can the machine be customized according to our specific bag size and material requirements?

A: Yes, we support full customization. We can adjust the bag size (minimum 5g small bags to maximum 5kg large bags), sealing type (heat sealing, ultrasonic sealing) and feeding system (screw feeding for powder, piston feeding for liquid, vibration feeding for granules) according to your material characteristics (powder, granule, liquid) and packaging specifications. The customization cycle is 30-45 days.

3. Q: What is the delivery time and shipping method? How to handle customs clearance?

A: Standard models can be delivered within 7-15 days, and customized models within 30-45 days. Shipping methods include sea freight (economical, suitable for bulk orders), air freight (fast, 3-7 days) and international express (for small parts). We will provide a full set of customs clearance documents (commercial invoice, packing list, certificate of origin, CE certification, fumigation certificate if needed) to ensure smooth customs clearance. We can also cooperate with your designated freight forwarder or arrange door-to-door delivery for you.

4. Q: What is the warranty policy and how to get after-sales service if there is a problem with the machine overseas?

A: We provide a 1-year warranty for all machines, covering main parts (motor, PLC, sensor). During the warranty period, we will send free spare parts and provide 24-hour online technical support (video guidance, remote debugging). For bulk orders or key customers, we can arrange engineers to go to the site for maintenance (the customer only needs to bear round-trip air tickets and accommodation). We also have spare parts warehouses in Germany and the United States, which can deliver parts within 3-5 days.

5. Q: How to determine the model that suits our production needs? Do you provide pre-sales testing?

A: Our sales engineers will confirm the key parameters with you first: 1. Material type (powder, granule, liquid, etc.); 2. Packaging speed requirement (bags/min); 3. Bag size and weight; 4. Production site size. Based on this, we will recommend the most suitable model. If you have samples of materials, you can send them to us, and we will conduct free packaging tests and send the test video and samples to you for confirmation, ensuring the machine meets your needs.

6. Q: What is the payment term and can we visit the factory before placing an order?

A: Our common payment terms are T/T (30% advance payment, 70% balance before delivery), L/C at sight is also acceptable. We warmly welcome you to visit our factory. We can arrange airport pickup, hotel reservation and factory tour. For customers who cannot come in person, we can provide a live video tour of the factory and production line. In addition, we participate in many international exhibitions every year (such as Germany Anuga, Shanghai CAC Fair), and you can also meet our team at the exhibition site.