Description

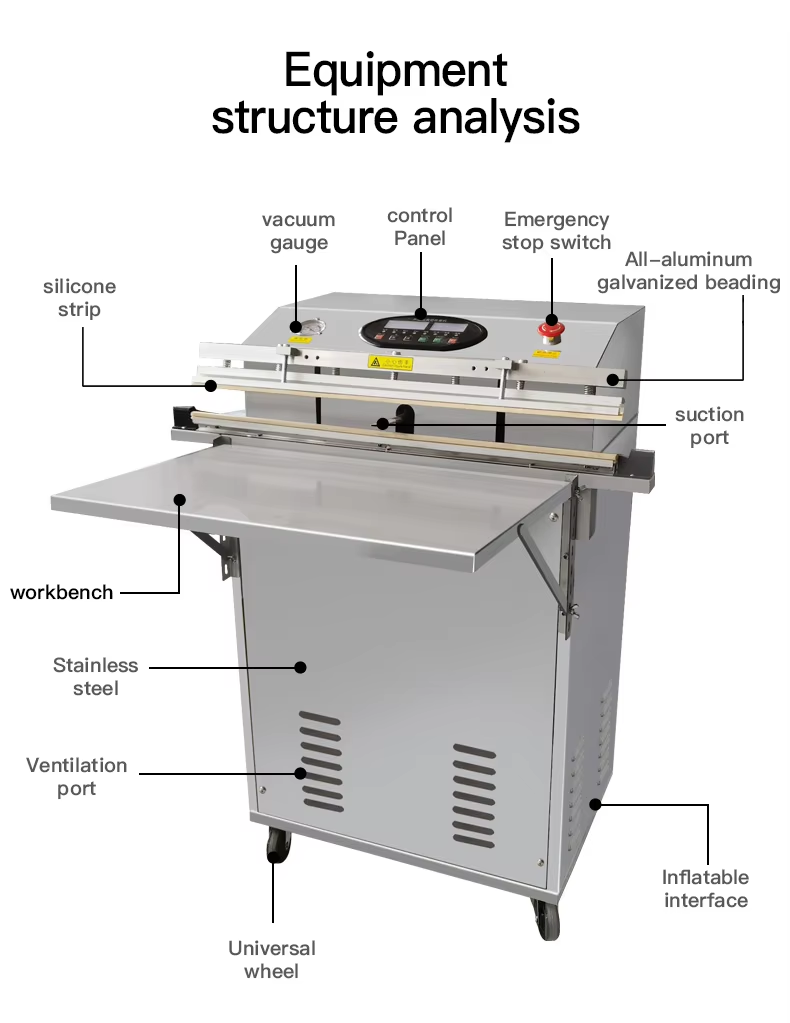

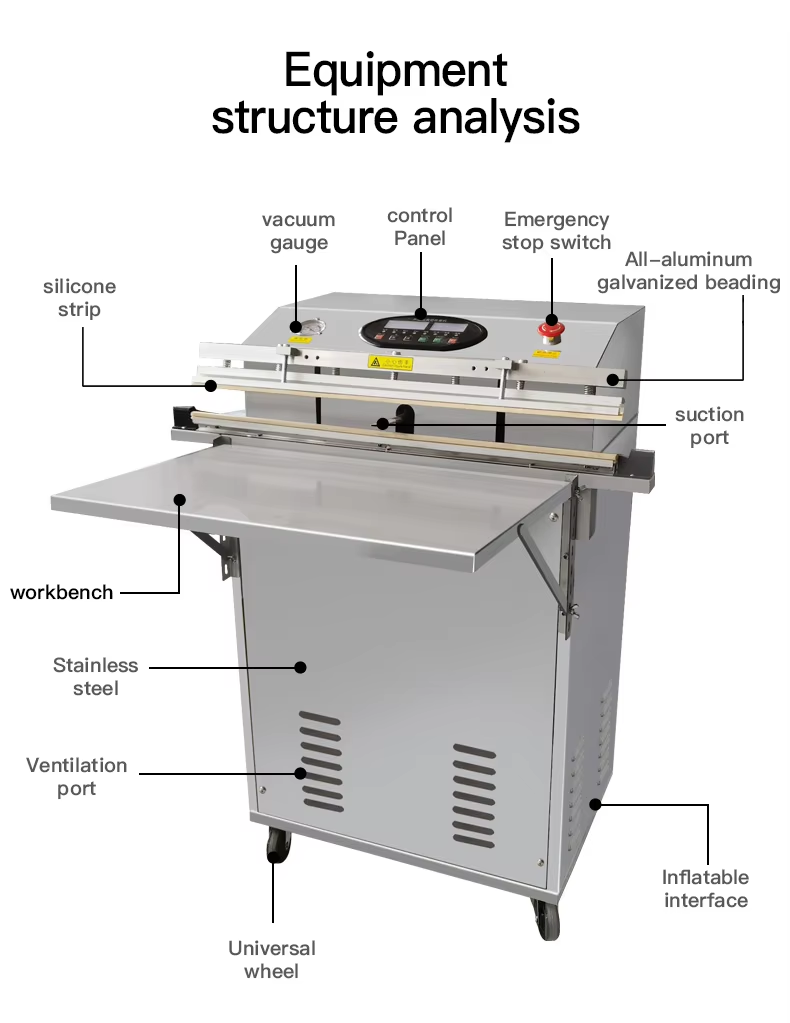

external type vacuum packaging machine

External vacuum packaging machine is a heavy-duty packaging solution engineered for sealing large, irregular-shaped products and bulk materials. Unlike internal vacuum sealers, our external type directly extracts air from the surface of the product and packaging bag, making it ideal for 5-50kg bags of food grains, electronic components, pharmaceutical supplies, and chemical powders. With a vacuum degree of -0.098MPa and dual-sealing technology, this machine ensures 100% leak-proof packaging, extends product shelf life by 2x, and meets the strict quality standards of the USA (NSF) and EU (CE/ROHS) markets.

Technical Parameter

Model

| EX-500 | EX-600 | EX-800 | EX-1000 |

| Voltage | 220V/50HZ | 220V/50HZ | 220V/50HZ | 220V/50HZ |

Power

| 1000W | 1500W | 2000W | 2500W |

| Weight | 40KG | 60KG | 65KG | 65KG |

| Pumping rate | 72L/Min | 108L/Min |

| Inflating rate | 0.8Mpa |

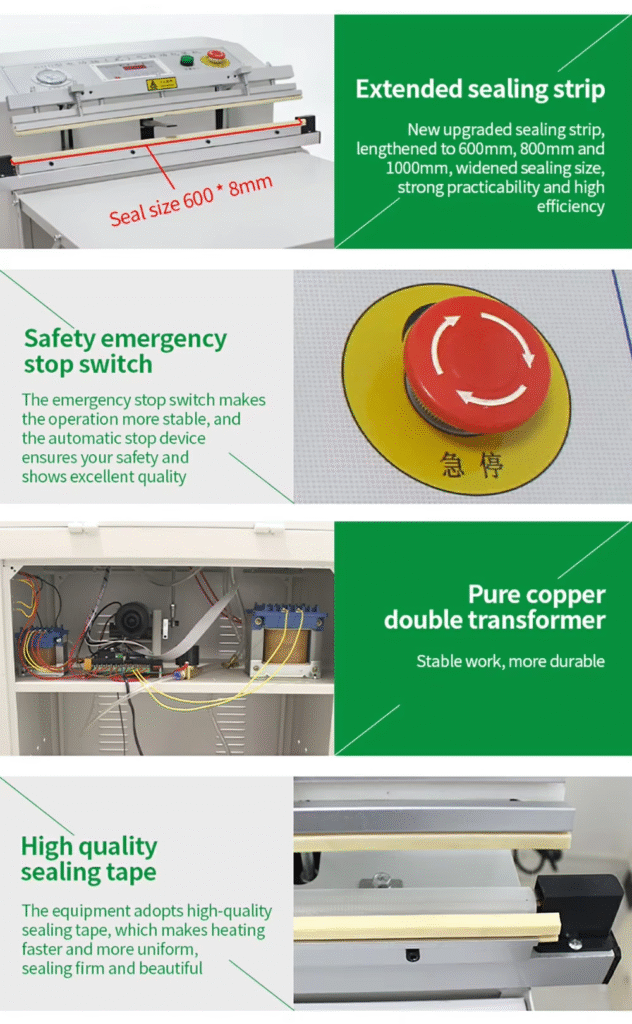

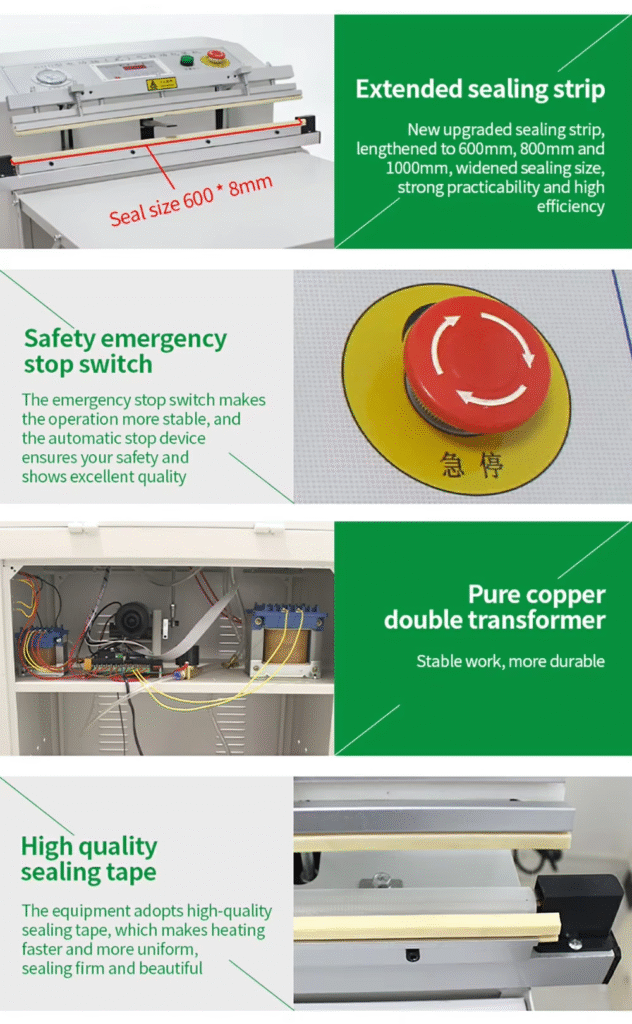

| Sealing size | 500x8mm | 600x8mm | 800x8mm | 1000x8mm |

| Dimension | 600x340x430mm | 700x450x950mm | 900x450x960mm | 1100x450x960mm |

Core Advantage

-

Superior External Vacuum Sealing Performance

The advanced external vacuum design extracts air far more efficiently than internal vacuum systems, creating a 100% airtight, leak-proof seal that locks in freshness, prevents oxidation, and extends product shelf life by up to 2x. Ideal for preserving perishable goods, electronics, and pharmaceuticals with maximum protection.

-

Precision Adjustable Settings for Versatile Packaging

Users can effortlessly customize vacuum cycle time, sealing temperature (100–250℃), and sealing pressure to match specific product requirements—from delicate food items to heavy-duty industrial parts. This flexibility ensures consistent, secure packaging results for every application, eliminating waste and rework.

-

Compact & Space-Saving Design for Small Workspaces

Its space-efficient external vacuum technology eliminates bulky internal chambers, allowing the machine to fit into tight factory floors, retail backrooms, or mobile packaging stations. A perfect choice for small and medium-sized businesses (SMBs) with limited operational space.

-

Heavy-Duty Stainless Steel Construction for Longevity

Crafted from food-grade 304 stainless steel, this external vacuum packaging machine is built to withstand 24/7 high-demand use in harsh environments—including wet food processing plants and dusty industrial facilities. Corrosion-resistant, rust-proof, and designed for years of reliable performance without degradation.

-

Intuitive User-Friendly Interface for Quick Operation

The streamlined, easy-to-navigate control panel features clear buttons and a digital display, enabling even first-time operators to master the machine in minutes. No specialized training required—reducing onboarding time and human error in high-volume production lines.

-

Energy-Efficient Design to Cut Operational Costs

Equipped with energy-saving vacuum pumps and intelligent power management, this machine minimizes electricity consumption by 15–20% compared to conventional models. Lower utility bills without sacrificing packaging speed or seal quality—ideal for cost-conscious businesses.

-

Multi-Industry Versatility for Diverse Applications

Whether sealing fresh meats, baked goods, pharmaceutical supplies, or electronic components, this external vacuum packaging machine works seamlessly with all bag types (PP, PE, laminated films) and sizes (5–50kg). A one-stop packaging solution for food processing, medical, and electronics industries.

-

High-Speed Packaging for Maximum Productivity

Engineered for high-volume operations, the machine delivers ultra-fast cycle times (≤3 seconds per vacuum seal) and consistent results, boosting packaging efficiency by 30% and meeting tight production deadlines for large batches.

-

Hygienic & Easy-to-Clean for Food Safety Compliance

Compliant with FDA and CE food safety standards, the smooth stainless steel surfaces and detachable components can be quickly wiped down or sanitized—reducing cleaning downtime and ensuring hygienic packaging for food and medical products. No hidden crevices to trap dirt or bacteria.

-

Low-Maintenance Design for Uninterrupted Use

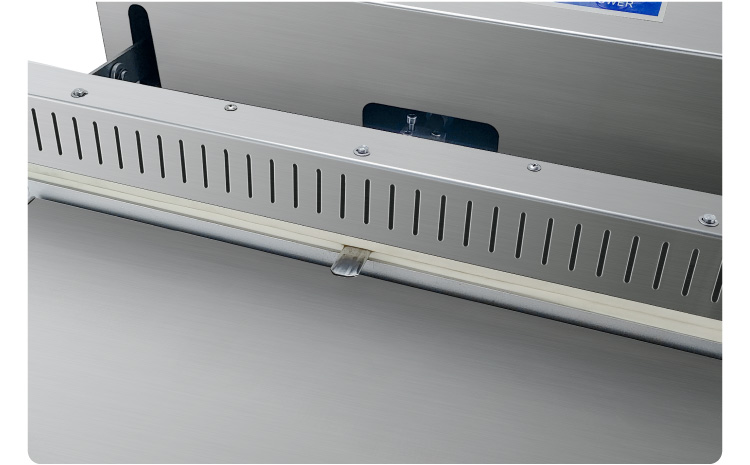

Built with wear-resistant core components (including heavy-duty vacuum pumps and sealing strips), this external vacuum packaging machine requires minimal maintenance. Fewer replacements and repairs mean lower long-term costs and reduced production downtime.

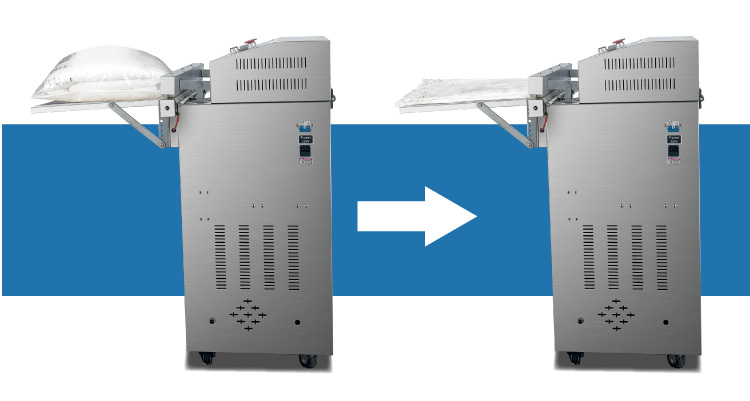

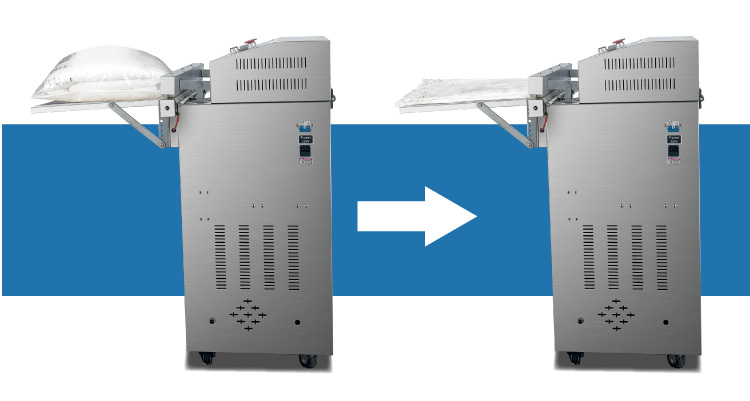

BREAKING THE LIMITATIONS OF VACUUM CHAMBERS

Vertical external vacuum extractor Easy to use and convenient

There is no requirement for packaging size

SUITABLE FOR

- Overlength cargo

- Bulk cargo

DUMP COMPRESSION DELIVER MORE CHEAPLY

Express freight calculation example

ADJUSTABLE ANGLE SUPPORTING PLATFORM

Suitable for upright operation of large bags

THE BODY IS MADE OF STAINLESS STEEL

Stainless steel frame, beautiful appearance, wet and corrosion resistance, easy to clean,Not easily deformed,long service life

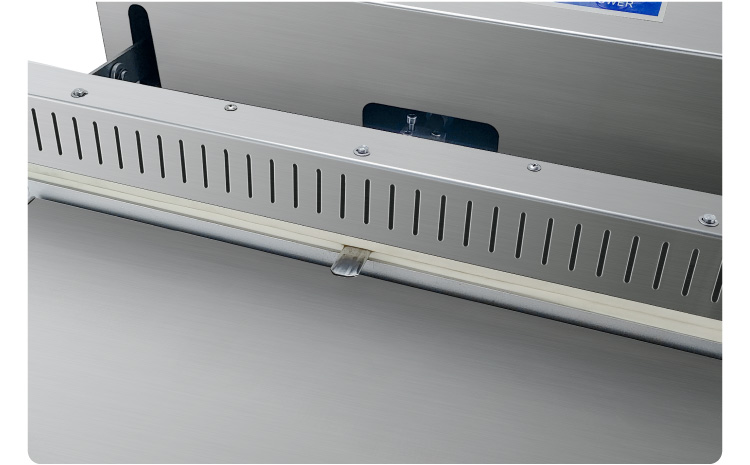

PNEUMATIC OPENING AND CLOSING SEAL

Pneumatic control seal

CONTROL PANEL

Easy to operate

Application

Our Factory

Our Certificate

FAQ

-

Q: What types of products can an external vacuum sealer handle, besides food items?

A: External vacuum sealers are highly versatile for non-food industrial applications. They excel at packaging electronic components (to prevent moisture, dust, and static damage), pharmaceutical supplies (sterile packaging for pills, medical devices, and lab reagents), chemical powders and granules (to avoid leakage and contamination), and metal parts (to prevent rust during storage and transportation). Unlike internal vacuum sealers, their chamber-free design can accommodate large or irregularly shaped items—from small circuit boards to 50kg bulk chemical bags.

-

Q: What vacuum degree is required for industrial non-food products, and how does it differ from food-grade applications?

A: For non-food industrial use, the required vacuum degree depends on the product’s protection needs:

- Electronics/pharmaceuticals: A vacuum degree of -0.095 to -0.098MPa is ideal to fully remove air and moisture, critical for preserving sensitive components and sterile supplies.

- Chemical/metal parts: A range of -0.08 to -0.09MPa is sufficient to prevent oxidation and leakage.

Compared to food applications (which prioritize shelf life extension), industrial use focuses more on environmental isolation—so the vacuum degree can be adjusted based on whether the product needs moisture-proof, dust-proof, or anti-corrosion protection.

-

Q: Do external vacuum sealers need specific certifications for industrial applications in different global markets?

A: Yes, certifications vary by region and industry:

-

Q: How to reduce maintenance costs and downtime for external vacuum sealers in high-demand industrial environments?

A: Follow these three practical tips for heavy industrial use:

① Regular cleaning: Wipe down sealing bars and vacuum nozzles daily to remove dust, powder, or residue—this prevents seal failure and component wear.

② Replace wear parts proactively: Swap PTFE-coated sealing strips every 6–12 months (depending on usage frequency) and vacuum pump filters every 3 months to maintain performance.

③ Choose suppliers with local support: Opt for brands with regional spare parts warehouses—this ensures replacement parts are delivered within 48 hours, minimizing production delays for industrial lines.

-

Q: What’s the difference between an external vacuum sealer and an internal vacuum sealer for industrial packaging, and which is better?

A: The key difference lies in packaging flexibility and size compatibility, making external sealers the better choice for most industrial scenarios:

- External vacuum sealers: No built-in chamber—can handle unlimited product sizes (from small parts to large bulk bags) and irregular shapes. Ideal for industrial batch production and large-item packaging.

- Internal vacuum sealers: Limited by chamber size—only suitable for small, uniform products (e.g., small electronic components in retail packs).

For high-volume industrial operations, external vacuum sealers are more efficient, versatile, and cost-effective, as they eliminate the need for multiple machines to accommodate different product sizes.