HXH-250X Pillow Type Automatic Horizontal Packaging Machine

Pillow Type Automatic Horizontal Packaging Machine: High-Efficiency HFFS Pillow Pack Solution

Description

HXH-250X Horizontal Flow Wrapper – High-Speed HFFS Solution

Pillow Type Automatic Horizontal Packaging Machine is a professional horizontal form-fill-seal (HFFS) equipment designed for automatic bag forming, filling, sealing and cutting. Widely used in food (biscuits, cakes, chocolates), pharmaceuticals (test kits) and daily necessities industries, it adopts servo control technology to achieve ±0.5mm sealing precision and 300 packs/min high speed. With 15% film-saving design and non-stop film change function, it effectively reduces production costs for enterprises.

Technical Parameters

| Type | HXH-250X |

|---|---|

| Film width | Max.250mm |

| Bag length | 65~190mmor120~280mm |

| Bag width | 30~110mm |

| Product height | Max.55mm |

| Film roll diameter | Max.350mm |

| Packaging rate | 40~180 bag/min |

| Power | 220V,50/60HZ,2.4Kw |

| Machine size | (L)3770×(W)670×(H)1320mm |

| Machine quality | about 480Kg |

Working Principle

The whole working process of the horizontal flow wrapper is fully automatic, with 6 key steps to ensure stable and efficient operation:

-

Feeding: Products are conveyed to the feeding port evenly by the adjustable conveyor belt, adapting to different product sizes.

-

Bag Forming: Packaging film is folded and formed into pillow-shaped bags by the adjustable bag former, with adjustable bag length (60-600mm).

-

Vertical Sealing: The side of the bag is sealed by the intelligent temperature-controlled heating block, ensuring tight sealing without leakage.

-

Filling: Products are accurately filled into the formed bag, with optional nitrogen flushing function for snacks and frozen food.

-

Horizontal Sealing & Cutting: The top of the bag is sealed and cut into individual packs by the double-knife cutting system, with neat cutting edges.

-

Discharging: Finished products are conveyed to the next process automatically, realizing continuous production.

Core Advantages

-

Servo Independent Control: Adopts imported servo motor to realize precise control of bag length and sealing position, with sealing precision up to ±0.5mm and sealing qualification rate of 99.6%, avoiding waste caused by offset.

-

High Speed & Film Saving: The maximum speed reaches 300 packs/min, 20% higher than the industry average. The intelligent empty bag detection function avoids empty packaging, saving 15% of packaging film cost annually.

-

Non-stop Film Change & Fault Self-diagnosis: Support non-stop film change during operation, reducing downtime by 30%. The intelligent HMI system can automatically detect faults and display error codes, realizing quick troubleshooting.

-

Food-grade & Customizable: The contact part with products is made of 304 stainless steel, meeting FDA and CE standards. Support custom functions such as euro slot, punch hole and easy tear opening.

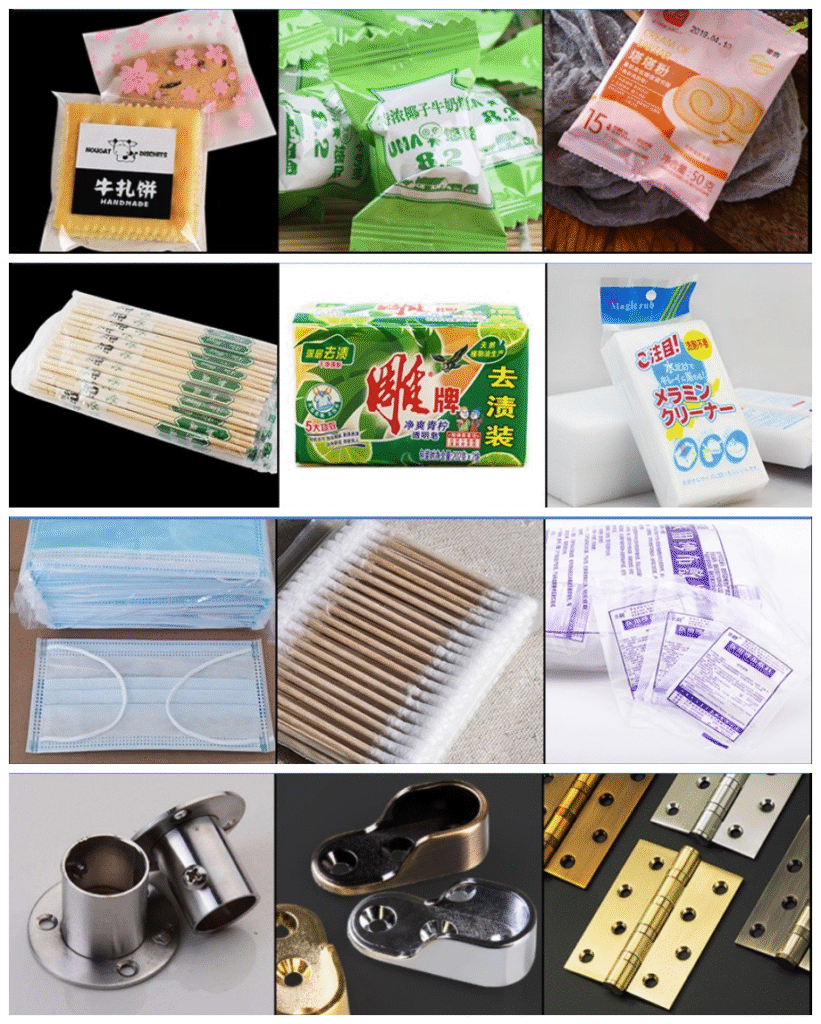

Applications of Pillow Type Automatic Horizontal Packaging Machine

Our horizontal flow wrapper is widely used in multiple industries, providing customized packaging solutions for different products:

-

Food Industry: Biscuits, cakes, chocolates, wafers, snacks, frozen dumplings, cooked food. Optional nitrogen flushing function to extend shelf life by 2-3 times.

-

Pharmaceutical Industry: Medical test kits, cotton swabs, band-aids. Meet GMP standards, with dust-proof and anti-static design to ensure product cleanliness.

-

Daily Necessities Industry: Paper towels, soap, wet wipes, toothbrushes. Support euro slot and punch hole design for convenient display and sales.

-

Hardware & Electronics Industry: Screws, nuts, connectors, small electronic components. With anti-collision design to avoid product damage during packaging.

Case Show: A large biscuit factory in Indonesia purchased 3 sets of [Brand]-350 pillow packaging machines, increasing daily output from 50,000 packs to 120,000 packs, and reducing film cost by 12% monthly.

How to Choose the Right Pillow Type Automatic Horizontal Packaging Machine?

4 key factors to help you select the most cost-effective equipment:

-

Production Capacity: If daily output is <50,000 packs, choose HXH-250/350; if >100,000 packs, choose HXH-450/600.

-

Product Size: Confirm the maximum length, width and height of the product, and match the corresponding film width and bag length range.

-

Special Functions: Snacks need nitrogen flushing, retail products need euro slot, medical products need GMP certification.

-

Regional Standards: European and American markets need CE certification, Southeast Asian markets focus on cost-effectiveness and after-sales service.

Certification & Professional After-sales Service

Our Pillow Type Automatic Horizontal Packaging Machine has passed CE, FDA and ISO9001 certifications, meeting international quality standards. We provide 1-year free warranty, 24-hour online technical support, and on-site maintenance service in key regions (Southeast Asia, Europe, North America). Spare parts warehouses are set up in Indonesia and Germany to ensure quick supply of spare parts.

Our factory

FAQ

Q. What is the maximum packaging speed of the HXH-250X pillow type automatic horizontal packaging machine?

Q. Which products is the HXH-250X pillow packaging machine suitable for packaging?

Q. What film materials are compatible with the HXH-250X pillow type packaging machine?

Q. Does the HXH-250X packaging machine come with after-sales support and technical training?

Q. What are the power requirements and overall dimensions of the HXH-250X automatic horizontal packaging machine?

Standard technical parameters (for global compatibility):

Get Your Custom Pillow Packaging Solution Now!

Tell us your product type, size and production capacity, and we will provide you with free quotation, technical plan and on-site demo video within 24 hours.