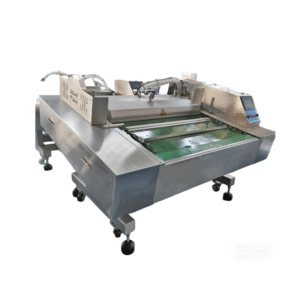

TB-5580 Automatic Skin Packing Machine

TB-5580 automatic vacuum skin sealer

1.Adopts right-in-right-out working plate movement driven by powered automatic rollers.

2.Equipped with a movable heater oven and constant heating technology to shorten cycling time significantly.

3.Features a USA-manufactured vacuum pump that provides strong vacuum displacement with exceptional quietness.

4.A dedicated safety cover is installed over the heater oven and heat-cut blade to fully protect operators during operation.

5.Standard configurations available, with tailor-made options (55×80 CM, 80×80 CM, 90×90 CM, etc.) to meet your specific packaging needs.

Description

TB-5580 Automatic Skin Packing Machine – Vacuum Sealer for Hardware/Auto Parts

hardware skin packaging machine

The skin packing machine for workpieces stands out as one of the most economical vacuum skin packaging solutions in the industrial sector, tailored to solve packaging pain points for hardware, auto parts, electronic components, and irregular workpieces. It integrates automatic heating, vacuum pumping, and sealing into one seamless process—no need for custom pattern dies—delivering tight, protective packaging while cutting costs and boosting efficiency.

Technical Parameter

| Model | TB-390 | TB-390S | TB-390S + Slide | TB-540 | TB-5580 |

|---|---|---|---|---|---|

| Voltage | 380V 50/60HZ 220V 50/60HZ | 380V 50/60HZ 220V 50/60HZ | 380V 50/60HZ 220V 50/60HZ | 380V 50/60HZ 220V 50/60HZ | 380V 50/60HZ 220V 50/60HZ |

| Power (kw) | 12 | 17 | 17 | 18 | 27 |

| Working Area (mm) | 390×540 | 390×540 | 390×540 | 540×780 | 550×800 |

| Vaccum Pump | 1 Vacuum pump | 1 vacuum pump+Vacuum box / 1 Vacuum pachine | 1 vacuum pump+Vacuum box / 1 Vacuum pachine | 2 Vacuum pump | 2 Vacuum machine |

| Packing speed (sec/pcs) | 15-40 | 13-30 | 13-30 | 20-50 | 20-50 |

| Applicable Packaging Film | PVC packaging film、PE packaging film、 Surlyn film、Professional PCB packaging film | ||||

| Film Width(mm) | 450 | 450 | 450 | 610 | 610 |

| Heating Method | Heating Tube | Heating wire / Heating tube | Heating wire / Heating tube | Heating tube | Heating tube |

| Total Weight | 140 | 200 | 220 | 240 | 300 |

| Dimension L×W×H (mm) | 1515×605×1355 | 1680×810×1430 | 1670×820×1450 | 1890×760×1355 | 2660×890×1410 |

| Packing Box Size L×W×H (mm) | 950×720×1460 | 1100×840×1480 | 1120×870×1480 | 1200×850×1500 | 1760×960×1450 |

Core Advantage

TB-5580 Automatic Vacuum Skin Packing Machine – Industrial-Grade Solution for Workpieces & Components

Applications of TB-5580 Skin Sealer

Why Choose the TB-5580?

FAQ

Q:Can the TB-5580 skin packing machine handle irregularly shaped workpieces like auto parts or small hardware?

A:Absolutely! The TB-5580 is specifically designed for irregular workpieces (e.g., auto radiators, small hardware, ferrite cores) — its vacuum skin technology conforms tightly to product contours without custom dies. To ensure perfect adaptation, simply send us your workpiece dimensions/photos, and we’ll provide a free packaging test video + customized solution within 24 hours.

Q: What is the film cost for the TB-5580, and do I need to use special film?

A:The TB-5580 is compatible with universal PE/PVC skin films (no special film required), which cost only $0.8–1.2 per square meter — 40% cheaper than dedicated films. We also offer a list of trusted film suppliers to help you control costs. If you need, we can send 1 roll of sample film (free of charge) for your test.

Q:How long is the warranty for the TB-5580, and what after-sales support is available?

A:We provide a 1-year full machine warranty and a 2-year warranty for core components (e.g., USA-made vacuum pump, heating elements). For any issues, our 7×24-hour technical team offers remote guidance; for overseas customers, we ship spare parts via DHL (3–5 day delivery) and provide video tutorials for easy maintenance.

Q: Can the TB-5580 be integrated into my existing production line, and is it easy to operate?

A:Yes! The TB-5580 is designed for seamless integration with most industrial production lines — it supports custom in-feed/out-feed height adjustments to match your workflow. Operation is simple: the intuitive control panel with English interface allows new operators to master it in 10 minutes, no professional training needed. We can also share a production line integration case video similar to your industry upon request.

Q:What custom sizes are available for the TB-5580, and how long does the customization take?

A:The TB-5580 offers flexible custom sizes, including 55×80cm, 80×80cm, 90×90cm, and other dimensions based on your workpiece needs. Customization takes only 15-20 working days (faster than industry average of 15 days). To get an accurate quote and delivery time, please tell us your required working area size and application scenario.