The Ultimate Buying Guide: Packaging Equipment for Dates, Sandwiches, Sausages, Cheese

Choosing the right packaging equipment is a make-or-break decision for food businesses. It directly impacts product freshness, shelf life, operational efficiency, and customer satisfaction. Different foods have unique characteristics—moisture content, fragility, perishability, and shape—that demand tailored packaging solutions. This guide dives into the best packaging equipment for five popular foods: dates, sandwiches, sausages, cheese, and steaks. We’ll focus on food-specific properties and packaging efficiency to help you make data-driven choices.

Key Factors to Consider Before Buying Food Packaging Equipment

Before exploring product-specific recommendations, clarify these core requirements to narrow down your options:

- Food Characteristics: Moisture (e.g., fresh steaks vs. dry dates), fragility (e.g., sandwiches vs. sausages), and preservability (e.g., cheese vs. pre-made sandwiches).

- Production Scale: Small bakeries (100-500 units/day) need different equipment than large meat processing plants (10,000+ units/day).

- Efficiency Metrics: Packaging speed (units/minute), labor requirements, and downtime rates.

- Regulatory Compliance: Food-grade materials (304/316 stainless steel) and compliance with FDA 21 CFR or EU 10/2011 standards.

- Packaging Goals: Extended shelf life, tamper resistance, or retail-ready presentation.

1.Dates: Automatic Vertical Form-Fill-Seal (VFFS) Machines

Food Characteristics of Dates

Dates are high in natural sugars (60-70% sugar content) and moisture (15-25%), making them sticky and prone to clumping. They require dust-proof packaging to maintain cleanliness and airtight sealing to prevent moisture loss or absorption. Most date products are sold in pre-weighed portions (100g-500g) in stand-up pouches or zip-lock bags.

Recommended Equipment: Automatic VFFS Packaging Machines

Vertical Form-Fill-Seal (VFFS) machines are the gold standard for date packaging, as they integrate forming, filling, and sealing into one continuous process. Models like the MCGD8-260 (a industry-proven VFFS machine) offer tailored solutions for sticky, granular products .

Why It Works for Dates

- Anti-Stick Design: Food-contact parts are made of 316 stainless steel with a non-stick coating, preventing dates from clinging to the filling system.

- Precise Weighing: Equipped with multi-head weighers that handle clumpy dates, ensuring portion accuracy (error ≤±1g) for consistent retail packaging.

- Airtight Sealing: Combines hot-seal and cold-seal technology to create leak-proof seals for PE composite films or aluminum foil bags, extending shelf life by 3-6 months.

Efficiency Metrics

Production speed: 25-60 packs per minute (varies by date size and pouch type). Automatic bag width adjustment (via one-button motor control) reduces changeover time to 5 minutes or less—critical for businesses offering multiple date varieties (e.g., Medjool, Deglet Noor). For small-scale operations (50-200 packs/day), a semi-automatic VFFS machine with manual feeding is a cost-effective alternative.

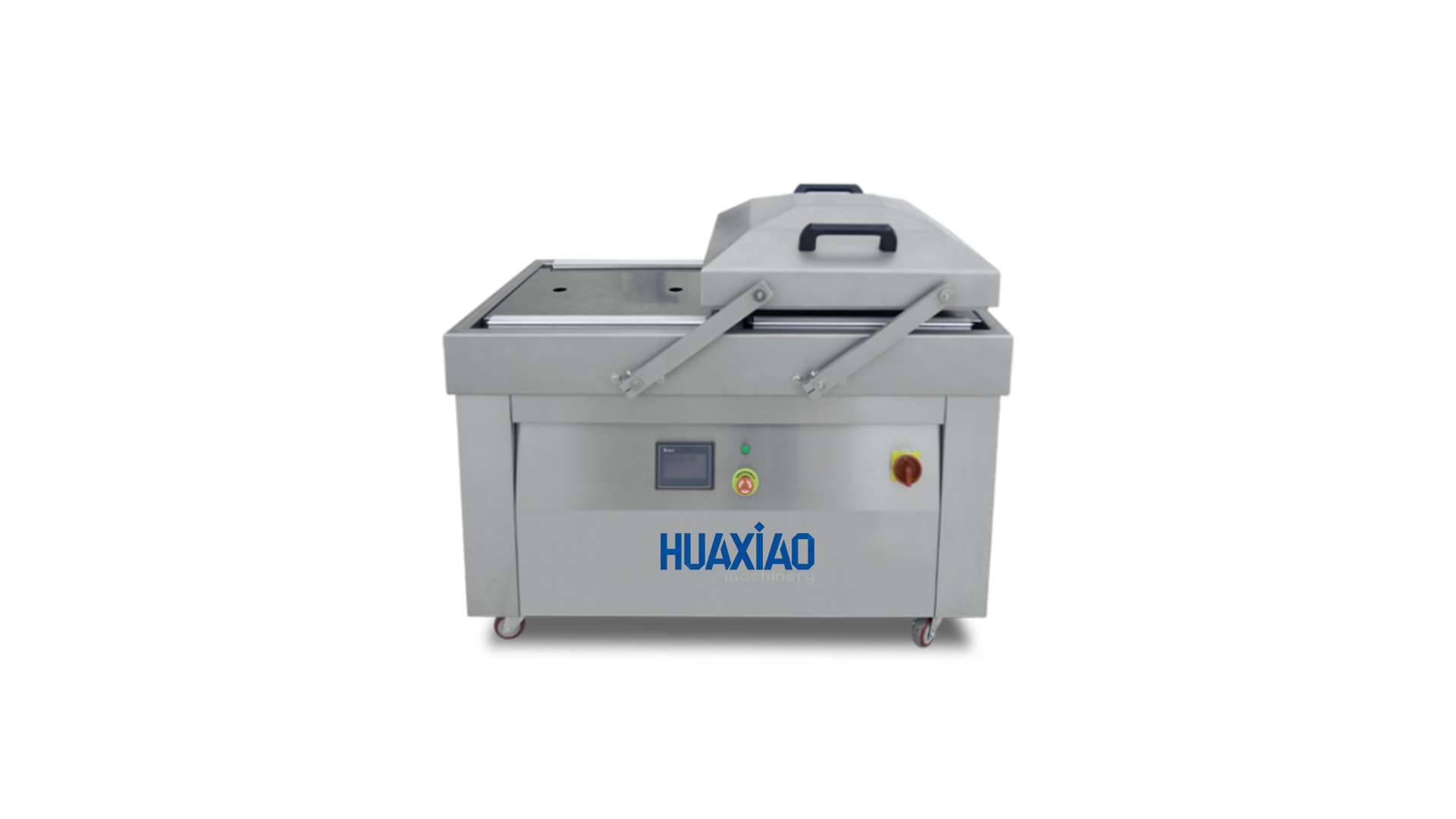

Alternative Equipment: Vacuum Packing Machines for Dates

While VFFS machines dominate large-scale date packaging, vacuum packing machines are a viable option for specific scenarios—especially small-batch producers, artisanal date brands, or businesses focusing on extended shelf life for premium varieties. Vacuum packaging removes oxygen from pre-formed bags or pouches, inhibiting oxidation and microbial growth to preserve date quality .

Why It Works for Dates (and Ideal Scenarios)

- Enhanced Shelf Life: By eliminating oxygen, vacuum packing extends date shelf life to 18-24 months at room temperature—far longer than the 3-6 months from standard VFFS packaging . This is ideal for exporters or businesses targeting long-term storage.

- Moisture & Freshness Lock: The airtight seal prevents moisture loss (which causes date hardening) and absorption (which leads to stickiness), maintaining the natural chewiness of varieties like Medjool .

- Small-Scale Affordability: Semi-automatic vacuum packers (e.g., Tabletop models from Weston or VacMaster) have lower upfront costs than VFFS machines, making them perfect for family-owned date farms or specialty food shops producing 20-50 packs/hour.

- Anti-Insect Protection: Oxygen-free environments deter pantry pests like weevils, a common issue with traditional date storage methods .

Key Considerations for Date Vacuum Packing

- Anti-Stick Modifications: Opt for machines with Teflon-coated seal bars and wide gusseted bags to prevent sticky date residues from compromising seals. Some models offer “dry mode” to handle sugary surfaces .

- Vacuum Pressure Adjustment: Use low to medium pressure (0.3-0.5 bar) to avoid crushing soft, fresh dates. Harder, dried dates can tolerate higher pressure for tighter seals .

- Film Compatibility: Choose multi-layer PE or PA/PE composite films that resist punctures from date pits and are safe for food contact (compliant with FDA 21 CFR) .

- Efficiency Tradeoffs: Fully automatic vacuum packing lines process 30-60 packs/minute—slower than VFFS machines—but require less operator training. Changeover between pack sizes takes 10-15 minutes .

- Storage Recommendations: Even with vacuum packaging, store dates in cool (15-20℃) and dark environments to prevent sugar crystallization. For frozen storage (-18℃), vacuum packs maintain quality for up to 2 years .

VFFS vs. Vacuum Packing: How to Choose

Select VFFS machines if you need high-speed production (25+ packs/minute), stand-up pouches for retail displays, or frequent flavor/variety changes. Choose vacuum packing if your priority is extended shelf life, small-batch production, or cost-effectiveness for premium, low-volume date products.

2.Sandwiches: Modified Atmosphere Packaging (MAP) Tray Sealers

Food Characteristics of Sandwicheskm

Sandwiches are fragile (layered structure, delicate bread) and highly perishable (contains fresh veggies, meats, or dairy). They require gentle handling to avoid squishing and gas-modified packaging to slow bacterial growth. Retail-ready presentation (clear visibility of fillings) is also a key marketing requirement.

Recommended Equipment: Automatic MAP Tray Sealers

MAP tray sealers are designed to address the dual needs of preservation and product integrity. They seal pre-formed plastic trays with a gas mixture (typically 70% CO₂ + 30% N₂) that inhibits mold and keeps bread fresh .

Why It Works for Sandwiches

- Gentle Handling: Conveyor systems with soft grips and low-speed transfer prevent tray deformation or filling displacement.

- Extended Freshness: MAP technology reduces oxygen levels to <0.5%, extending shelf life from 1-2 days (traditional packaging) to 5-7 days .

- Retail-Ready Design: Clear PET trays and transparent lidding films showcase the product, while tamper-evident seals build consumer trust.

Efficiency Metrics

Medium-scale operations (500-2,000 sandwiches/day) benefit from semi-automatic models (30-50 trays/minute) with manual tray loading. Large bakeries or catering companies should opt for fully automatic lines (80-120 trays/minute) with integrated tray feeding and date coding. Most models comply with FDA 21 CFR standards for food contact .

3.Sausages: Flow Pack Machines (Horizontal Form-Fill-Seal)

Food Characteristics of Sausages

Sausages are cylindrical, flexible, and often sold in multi-unit packs (4-6 links). They require tight, wrinkle-free packaging to prevent freezer burn (for frozen sausages) and high-speed processing (sausage production lines have high output). Some varieties (e.g., dry-cured sausages) need breathable packaging, while fresh sausages require airtight seals.

Recommended Equipment: Automatic Flow Pack Machines

Flow pack machines (horizontal form-fill-seal) are ideal for long, cylindrical products like sausages. They form a tube of film around the product as it moves horizontally, then seal and cut the film into individual or multi-unit packs .

Why It Works for Sausages

- High-Speed Sealing: Continuous horizontal movement enables fast processing, matching the output of sausage extruders.

- Customizable Packaging: Adjustable film tension creates tight wraps for frozen sausages (preventing ice crystals) or breathable micro-perforated films for dry-cured varieties.

- Multi-Unit Packs: Easy adjustment of cut lengths allows packaging of 2-link snack packs or 10-link family packs without tool changes.

Efficiency Metrics

Standard models handle 60-100 sausages per minute, while high-capacity lines (for meat processing plants) reach 150-200 units/minute. The machines use PE or PP films, and food-contact parts are 304 stainless steel for easy cleaning . For small butchers (100-300 sausages/day), a semi-automatic flow pack machine with manual product feeding is sufficient.

4.Cheese: Vacuum Packaging Machines with Gas Flushing

Food Characteristics of Cheese

Cheese varies widely (soft: Brie; hard: Cheddar; semi-hard: Gouda), but all require protection from oxidation (which causes discoloration) and mold growth. Soft cheeses are fragile and need low-pressure packaging, while hard cheeses can withstand tighter seals. Many artisanal cheeses benefit from controlled gas environments to preserve flavor.

Recommended Equipment: Automatic Vacuum Packers with MAP Function

Vacuum packaging removes oxygen to slow spoilage, and adding MAP (modified atmosphere) takes preservation a step further. Machines like those from Zeus Packaging offer dual vacuum-MAP capabilities for versatile cheese packaging .

Why It Works for Cheese

- Adjustable Vacuum Pressure: Low-pressure settings (0.2-0.4 bar) for soft cheeses prevent crushing, while high-pressure (0.6-0.8 bar) for hard cheeses creates tight seals.

- Flavor Preservation: A 90% N₂ + 10% CO₂ gas mixture maintains cheese texture—CO₂ inhibits mold, while N₂ prevents oxidation without affecting flavor.

- Hygienic Design: Smooth surfaces and detachable seal bars make cleaning easy, complying with dairy industry hygiene standards.

Efficiency Metrics

Semi-automatic machines (for small creameries) process 15-30 packs/minute, while fully automatic lines (for large cheese producers) handle 50-80 packs/minute. Vacuum-MAP packaging extends cheese shelf life by 2-3x compared to traditional wrapping—critical for distributing artisanal cheeses nationally .

-

Steaks: Skin Packaging Machines

Food Characteristics of Steaks

Fresh steaks are high in moisture and fat, requiring leak-proof packaging to prevent juice loss. They also need high visibility (consumers judge quality by marbling) and extended refrigerated shelf life. Frozen steaks need packaging that resists punctures and freezer burn.

Recommended Equipment: Automatic Skin Packaging Machines

Skin packaging uses a thin film that conforms tightly to the steak’s shape, adhering to a rigid tray. This “second skin” design offers superior protection and presentation compared to traditional vacuum packs .

Why It Works for Steaks

- Juice Retention: The tight film seal traps meat juices, keeping steaks moist during storage and transportation.

- Enhanced Presentation: The conformal film highlights marbling and texture, increasing retail appeal. Clear trays allow 360° product visibility.

- Freezer-Ready: Compatible with freezer-grade films (e.g., PP) that resist cracking at -20℃, preventing freezer burn for up to 6 months.

Efficiency Metrics

Medium-scale butcher shops (200-500 steaks/day) use semi-automatic skin packers (20-40 packs/minute), while large meat processors opt for fully automatic lines (60-100 packs/minute). The machines integrate seamlessly with portioning scales and date coders for end-to-end processing .

Final Buying Checklist for Food Packaging Equipment

| 1. Match equipment to food characteristics (sticky, fragile, perishable).

2. Align speed with production volume (avoid overpaying for unused capacity). 3. Verify regulatory compliance (FDA, EU standards) for food contact parts. 4. Evaluate total cost of ownership (energy use, maintenance, film compatibility). 5. Test with your product (ask suppliers for sample runs). |

By prioritizing food-specific needs and efficiency, you’ll select packaging equipment that boosts productivity, reduces waste, and keeps your products fresh. For custom solutions (e.g., multi-product lines), consult with packaging specialists to design a system tailored to your business.