Thermoforming Vacuum Packaging Machine: Maintenance and Troubleshooting Tips

For food processors and manufacturing plant managers, a thermoforming vacuum packaging machine is the backbone of daily operations. When it runs smoothly, it ensures consistent packaging quality, meets production targets, and keeps costs in check. But unexpected breakdowns? They lead to costly downtime, missed deadlines, and wasted materials—especially for businesses shipping to international markets with tight delivery windows.

The good news is that 80% of common thermoforming vacuum packaging machine issues can be prevented with regular maintenance. And when problems do arise, quick troubleshooting can minimize disruption. This guide shares actionable maintenance routines, solves top common faults, and helps you get the most out of your investment—whether you’re using a semi-automatic model or a fully automatic MAP-equipped thermoformer.

Part 1: Daily & Weekly Maintenance Routines (Prevent Costly Breakdowns)

Preventive maintenance is far cheaper than repairing or replacing parts. A consistent routine not only extends your thermoforming vacuum packaging machine’s lifespan (from 5-7 years to 10+ years) but also maintains its efficiency and packaging quality. Below are tiered maintenance checklists tailored to different timeframes.

1.1 Daily Maintenance (5-10 Minutes Before/After Shifts)

These quick checks keep your machine running safely and smoothly day-to-day—assign them to the operator in charge of the thermoformer:

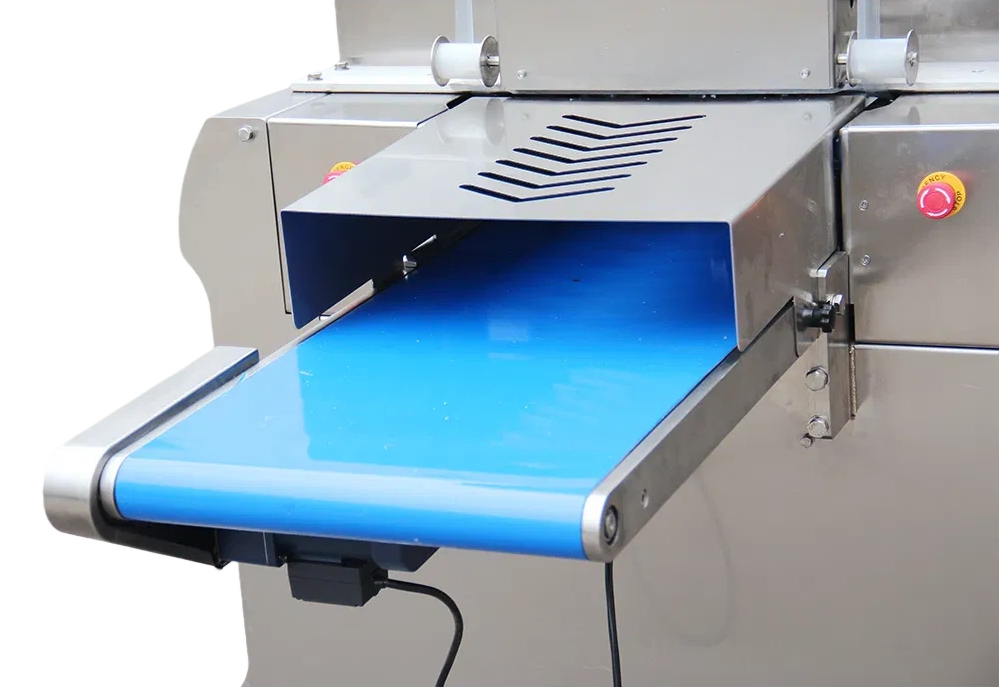

- Clean the Machine Exterior & Sealing Area: Wipe down the stainless steel 304 body with a food-grade sanitizer (compliant with FDA/CE standards) to remove food residue, oil, or dust. Pay extra attention to the sealing bar—residue buildup here causes uneven sealing or bag leaks. Use a soft brush to clean the sealing bar’s grooves, then wipe with a dry cloth.

- Inspect the Vacuum Pump Oil Level: Check the oil gauge on your Busch or equivalent vacuum pump. If the oil is below the “MIN” line, top it up with the manufacturer-recommended grade (never use generic oil—this damages the pump). Also, check for oil discoloration: clear or light amber oil is good; dark brown or cloudy oil means it’s time for a change.

- Test the Safety Features: Ensure emergency stop buttons, door interlocks, and temperature alarms work properly. For food safety and worker protection, never operate the machine if safety features are faulty.

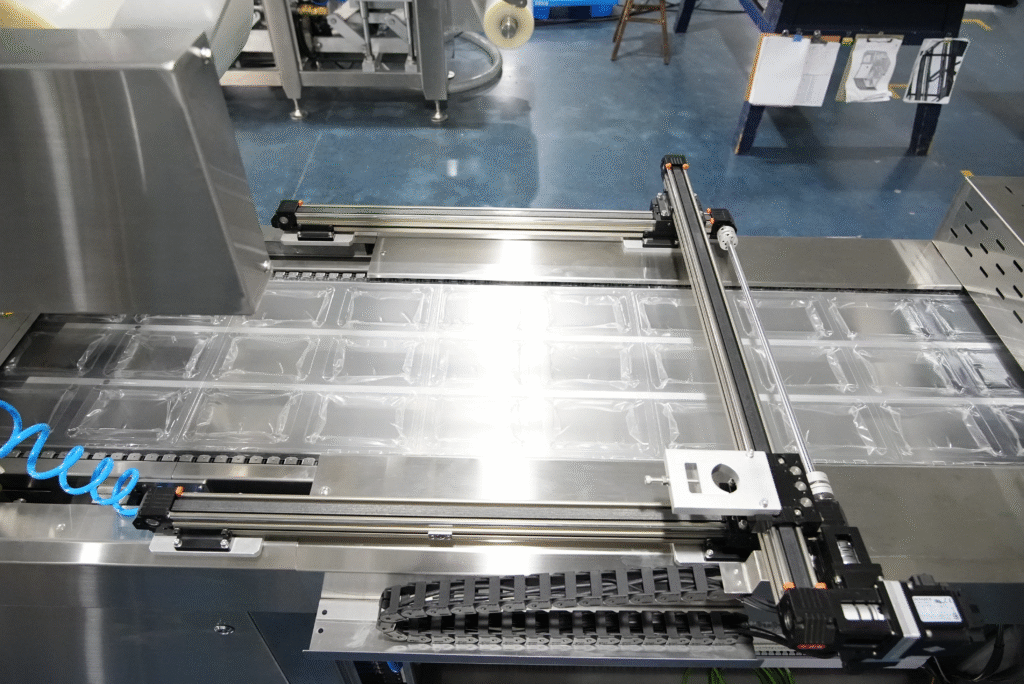

- Check Packaging Material Alignment: Verify that the film roll is loaded correctly and feeds smoothly through the forming station. Misaligned film causes material waste and uneven forming.

1.2 Weekly Maintenance (30 Minutes on Weekends or Slow Shifts)

Performed by maintenance staff, these checks address wear-and-tear that builds up over time:

- Lubricate Moving Parts: Apply food-grade lubricant to chains, gears, and guide rails (refer to your machine’s manual for specific lubrication points). Avoid over-lubricating—excess oil can transfer to packaging materials and contaminate food.

- Inspect Sealing Bar & Heating Elements: Check the sealing bar for scratches, dents, or uneven wear. If the bar is damaged, it will cause inconsistent sealing (e.g., some packages leak while others are over-sealed). Also, test heating element resistance with a multimeter—values outside the manufacturer’s range mean the element needs replacement.

- Clean the Vacuum Filter & Hoses: Remove and clean the vacuum filter (most are washable with warm water). Clogged filters reduce vacuum pressure, leading to poor packaging quality. Inspect hoses for cracks or leaks—replace any damaged hoses immediately.

- Calibrate Temperature & Vacuum Settings: Run a test batch with your standard packaging material (e.g., BOPP/PE film) and check if the sealing temperature and vacuum pressure match the recommended settings. Calibrate if needed—this ensures consistent results across production runs.

1.3 Monthly & Annual Maintenance (Professional Service Recommended)

For long-term reliability, schedule these deeper checks with your thermoforming vacuum packaging machine manufacturer or certified technician:

- Monthly: Inspect servo motors and drive systems for unusual noise or vibration. Check electrical connections for loose wires (tighten if needed) and replace worn carbon brushes in motors.

- Annual: Complete a full vacuum pump overhaul (change oil, clean internal components, replace seals). Inspect the forming mold for wear—polish or replace if it causes uneven film forming. Conduct a full safety audit to ensure compliance with local regulations (e.g., OSHA in the US, EU Machinery Directive).

| Pro Tip: Create a maintenance log to track daily/weekly checks, part replacements, and service dates. This not only helps you spot recurring issues early but also simplifies warranty claims—most manufacturers require proof of regular maintenance for warranty coverage. |

Part 2: Top 5 Common Faults & Troubleshooting (Solve Issues in Minutes)

Even with perfect maintenance, occasional issues arise. Below are the most frequent problems with thermoforming vacuum packaging machines, their root causes, and step-by-step fixes—no advanced technical skills required.

2.1 Fault: Poor Vacuum Pressure (Packages Don’t Seal Tightly)

Symptoms: Bubbles in packages, short shelf life, or the machine displays a “low vacuum” error.

Causes & Fixes:

- Clogged Filter or Hose: Check the vacuum filter (clean or replace if clogged) and hoses (remove kinks or replace cracked ones). This is the most common cause—resolve it first.

- Worn Vacuum Pump Seals: If cleaning the filter doesn’t help, inspect the pump’s O-rings and seals. Replace any that are cracked or hardened (use manufacturer-approved parts).

- Leaky Sealing Chamber: Check the chamber gasket for wear. If it’s compressed or torn, replace it—this creates an airtight seal for proper vacuuming.

2.2 Fault: Uneven Sealing (Some Packages Leak, Others Are Over-Sealed)

Symptoms: Inconsistent seal quality, film melting in some areas, or packages that open during shipping.

Causes & Fixes:

- Residue on Sealing Bar: Clean the sealing bar with a food-grade solvent (avoid abrasive cleaners) to remove oil or food buildup.

- Damaged Sealing Bar or Heating Element: Inspect the bar for dents—if damaged, have it repaired or replaced. Test heating elements with a multimeter and replace faulty ones.

- Incorrect Temperature or Pressure Settings: Adjust the sealing temperature (increase by 5-10°C if seals are weak, decrease if film melts) or pressure (ensure even pressure across the bar). Refer to your material’s recommended settings (e.g., PE film needs lower temp than aluminum foil).

2.3 Fault: Film Doesn’t Form Properly (Uneven or Wrinkled Trays)

Symptoms: Film doesn’t conform to the mold, creates wrinkles, or tears during forming.

Causes & Fixes:

- Incorrect Heating Temperature: If the film is under-heated, it won’t form; if over-heated, it tears. Adjust the forming temperature per the film’s thickness (thicker film needs higher temp).

- Mold Issues: Clean the mold with a soft brush to remove residue. If the mold is scratched or worn, polish it or contact your manufacturer for a replacement.

- Film Tension Problems: Check the film roll’s tension settings—too tight causes tearing, too loose causes wrinkles. Adjust the tension knobs on the film feeding station.

2.4 Fault: Machine Runs Slow or Jams Frequently

Symptoms: Production speed drops below the machine’s rated capacity, or the machine stops mid-cycle with a “jam” error.

Causes & Fixes:

- Lack of Lubrication: Lubricate chains, gears, and guide rails with food-grade lubricant (refer to the manual for points).

- Debris in the Machine: Shut off power and remove any stuck film, food residue, or loose parts from the forming/sealing stations.

- Overloaded Motor: Check if the machine is processing more than its rated capacity (e.g., a 10-cycle/min machine can’t handle 15 cycles/min). Reduce production load and let the motor cool down.

2.5 Fault: MAP Function Doesn’t Work (Shelf Life Doesn’t Extend)

Symptoms: Packages have normal vacuum but shelf life is the same as traditional packaging; gas mix display shows irregular values.

Causes & Fixes:

- Gas Cylinder Issues: Check if CO2/N2 cylinders are full and valves are open. Replace empty cylinders and ensure regulators are set to the correct pressure (typically 0.4-0.6 MPa).

- Gas Mixer Calibration: If the gas mix is inaccurate, recalibrate the mixer (follow the manufacturer’s guide) or contact a technician for professional calibration.

- Leaky Gas Lines: Inspect MAP gas lines for cracks—replace any damaged lines and tighten loose connections.

Part 3: Pro Tips for Maximizing Machine Lifespan & ROI

Beyond maintenance and troubleshooting, these strategies help you get the most value from your thermoforming vacuum packaging machine:

3.1 Use High-Quality Parts & Materials

Never cut corners with cheap replacement parts (e.g., generic vacuum pump oil, non-food-grade lubricant) or low-quality packaging film. Inferior parts cause frequent breakdowns, while poor film leads to more waste and rework. Stick to manufacturer-approved parts and film—they cost slightly more but reduce long-term costs.

3.2 Train Operators & Maintenance Staff

Human error is a top cause of machine damage. Ensure operators know how to load film, adjust settings, and perform daily checks. Train maintenance staff on weekly checks and basic troubleshooting. Many manufacturers (including us) offer free on-site or virtual training for new machines—take advantage of it.

3.3 Schedule Preventive Maintenance with Your Manufacturer

While in-house teams can handle daily/weekly checks, annual professional service is worth the investment. Manufacturers know their machines best and can spot hidden issues (e.g., worn servo motors) before they cause major downtime. Our annual maintenance package includes a full inspection, part replacement discounts, and priority technical support.

3.4 Upgrade Aging Machines (When to Replace vs. Repair)

If your machine is over 8 years old and requires frequent repairs (more than 3 times per month), it’s often cheaper to upgrade than to keep fixing it. Newer fully automatic thermoforming vacuum packaging machines are 30% more energy-efficient and 20% faster than older models—they pay for themselves in 1-2 years through reduced maintenance and increased productivity.

Get Expert Support for Your Thermoforming Vacuum Packaging Machine

Even with the best maintenance, every machine needs professional help occasionally. Whether you’re troubleshooting a persistent fault, need replacement parts (e.g., sealing bars, vacuum pump seals), or want to schedule annual service, our team of certified technicians is available 24/7 for global support.

Our thermoforming vacuum packaging machines—from semi-automatic models to fully automatic MAP-equipped systems—are designed for easy maintenance and long reliability, with CE/FDA certification and a 2-year warranty. We also provide customized maintenance plans tailored to your production volume and usage frequency.

| Need Immediate Help? Contact our technical support team via email or WhatsApp for instant troubleshooting. For scheduled maintenance or part orders, fill out the form below to get a personalized quote. |