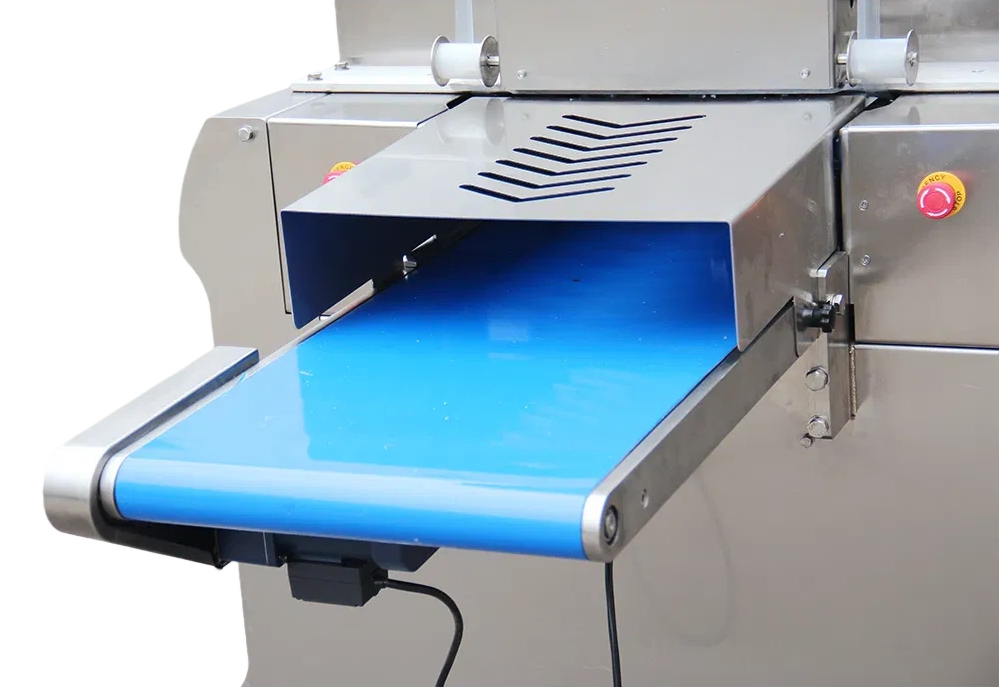

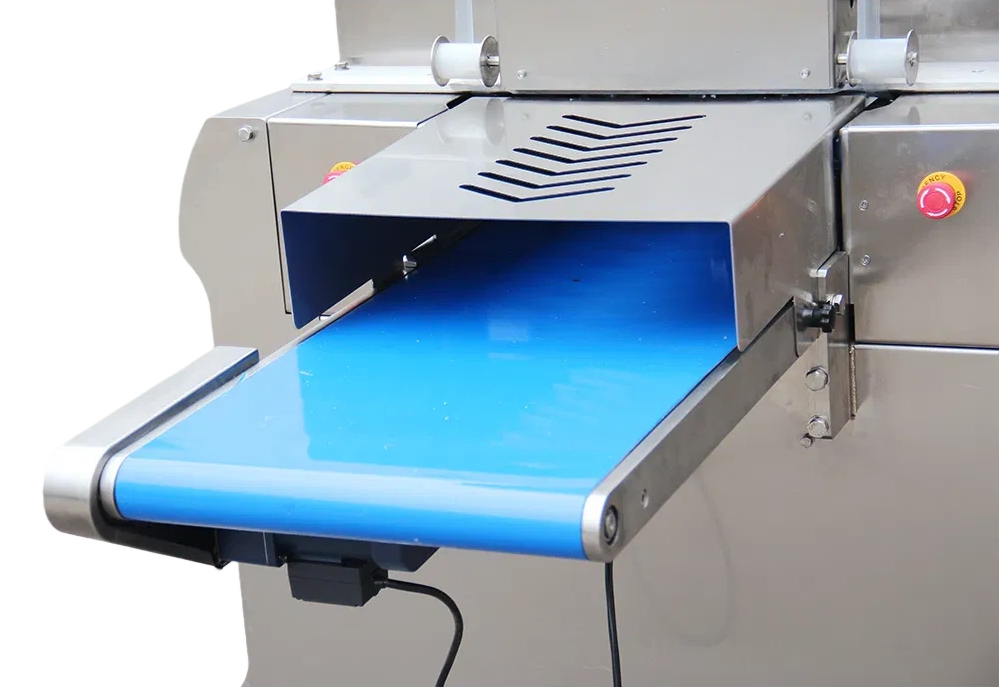

For small and medium-sized (SME) sausage factories, choosing the right packaging equipment is crucial to ensuring product freshness, improving production efficiency, and controlling costs. Among various packaging solutions, the thermoforming vacuum packaging machine stands out due to its flexibility, cost-effectiveness, and excellent preservation performance—key advantages that make it a top choice for SME operations.

This guide will walk you through the key considerations for selecting a high-performance, affordable thermoforming vacuum packaging machine that fits your SME sausage factory’s unique production needs and budget constraints.

1. Clarify Production Needs to Narrow Down Thermoforming Vacuum Packaging Machine Options

First, clarify your production needs to narrow down thermoforming vacuum packaging machine options. SME sausage factories typically face challenges such as limited production space, diverse product SKUs, and tight budget constraints—factors that directly influence which thermoforming vacuum packaging machine model is the best fit.

When evaluating potential machines, start with production capacity: compact thermoforming vacuum packaging machine models with a speed of 4-6 cycles per minute are suitable for small-scale production (below 5,000 sausages per day), while mid-range models (6-9 cycles per minute) can meet medium-scale demands (5,000-15,000 sausages per day).

Additionally, consider your product specifications—ensure the thermoforming vacuum packaging machine’s maximum forming depth (usually 120-160mm) and film width (320-520mm) match your sausage sizes, whether they are small snack sausages or large premium sausages. For factories with limited floor space, compact thermoforming vacuum packaging machine models are particularly worth considering as they occupy less area while maintaining basic functionality.

2. Focus on Core Performance Parameters of Thermoforming Vacuum Packaging Machine

Focus on core performance parameters of the thermoforming vacuum packaging machine that directly affect packaging quality. Vacuum degree is non-negotiable for sausage preservation; aim for a thermoforming vacuum packaging machine that reaches at least -0.09MPa to effectively remove air, inhibit microbial growth, and extend shelf life.

Equally important is the vacuum pump of the thermoforming vacuum packaging machine—brands like Busch offer high-efficiency pumps that reduce energy consumption and operating costs. Sealing quality is another critical factor: look for thermoforming vacuum packaging machine models with precise temperature control (error ≤±1℃) and nickel-chromium alloy heating strips to ensure tight, uniform seals that prevent leakage.

For food safety compliance, prioritize thermoforming vacuum packaging machines with 304 stainless steel contact parts, which are corrosion-resistant, easy to clean, and meet food-grade standards. Many reliable thermoforming vacuum packaging machine suppliers can provide certification for food safety compliance, which is a key factor in supplier evaluation.

3. Evaluate Flexibility and Ease of Operation of Thermoforming Vacuum Packaging Machine

Evaluate flexibility and ease of operation of the thermoforming vacuum packaging machine to adapt to diverse production needs. SME sausage factories often produce multiple sausage varieties, so a thermoforming vacuum packaging machine with removable, drawer-type molds is ideal—it allows quick mold changes for different product shapes (e.g., round, rectangular) or sizes without lengthy downtime.

A user-friendly PLC touch screen (10-inch or larger) on the thermoforming vacuum packaging machine simplifies operation, enabling staff to master settings without extensive training. Safety features of the thermoforming vacuum packaging machine should not be overlooked; choose models with multiple sensors that trigger auto-stop when covers or doors are opened to protect operators and avoid production accidents.

4. Consider Total Cost of Ownership of Thermoforming Vacuum Packaging Machine

Consider total cost of ownership of the thermoforming vacuum packaging machine beyond the initial purchase price. Energy efficiency is key—select thermoforming vacuum packaging machine models with energy-saving motors to reduce long-term electricity costs. Also, check the availability and cost of consumables for the thermoforming vacuum packaging machine (e.g., heating strips, seals) and the machine’s maintenance requirements; modular designs that allow easy access to components will minimize downtime and repair costs.

Finally, partner with suppliers that offer reliable after-sales service for thermoforming vacuum packaging machines, including on-site training, 48-hour maintenance response, and a minimum 1-year warranty. Some suppliers can also integrate third-party equipment (e.g., metal detectors, labelers) with the thermoforming vacuum packaging machine to create a seamless production line.

When comparing quotes, don’t just focus on the upfront price; calculate the long-term cost of the thermoforming vacuum packaging machine, including maintenance, consumables, and energy consumption.

5. Summary: Key Takeaways for Selecting Thermoforming Vacuum Packaging Machine

In summary, selecting the right thermoforming vacuum packaging machine for your SME sausage factory requires balancing production needs, performance, flexibility, and cost. By prioritizing the right capacity, core parameters, user-friendliness, and supplier support when choosing a thermoforming vacuum packaging machine, you can invest in equipment that enhances product quality, boosts efficiency, and supports business growth.

Remember, the best thermoforming vacuum packaging machine is not the most expensive one, but the one that perfectly aligns with your specific operational requirements and long-term development goals.

For SME sausage factories seeking cost-effective packaging solutions, a well-chosen thermoforming vacuum packaging machine is an investment that pays off in the long run.